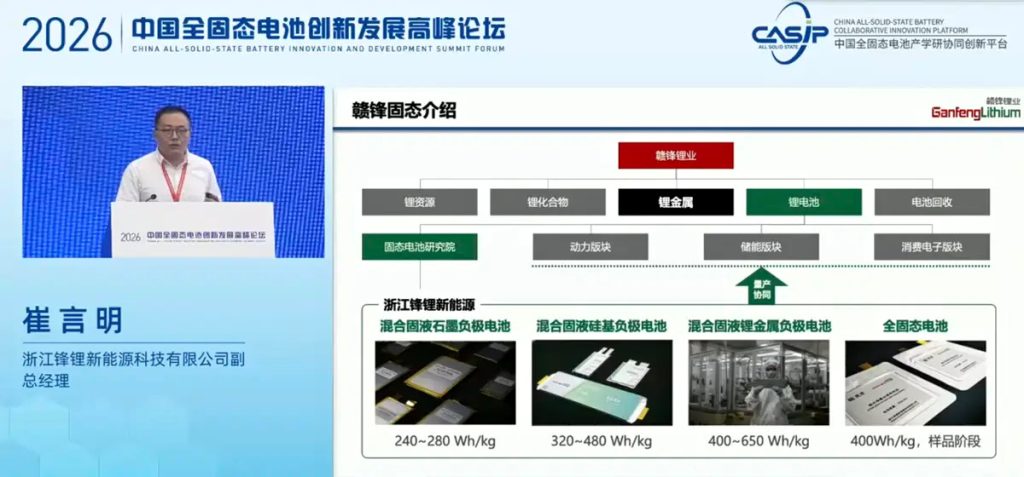

The world’s largest producer of lithium metal, Ganfeng Lithium, has reportedly begun mass-producing semi-solid-state batteries with an impressive energy density of 650 Wh/kg. The lithium giant has supply deals with Tesla, Volkswagen, Hyundai, and several other major OEMs for key EV battery materials.

Ganeng Lithium advances solid-state EV batteries

Ganfeng is China’s largest lithium compounds producer and the world’s leading lithium metals manufacturer. It accounts for roughly 45% of the global lithium metal market and 70% in China.

The company has secured deals with Tesla, Hyundai, BMW, Volkswagen, and several leading Chinese automakers to supply key EV battery materials.

Most recently, Ganfeng and Hyundai signed a four-year deal to supply lithium hydroxide, a critical raw material for EV batteries.

Advertisement – scroll for more content

Ganfeng offers a full range of lithium battery products, including solid-state batteries and lithium iron phosphate for EVs, energy storage systems, industrial equipment, and more.

In its latest milestone, company officials announced a new lithium-hybrid semi-solid-state battery with an energy density of 400-650 Wh/kg. According to China’s Autohome, the new battery is currently designed for non-automotive use. However, the new battery tech will likely make its way into upcoming electric vehicles.

Ganfeng headquarters R&D Center (Source: Ganfeng)

Ganfeng headquarters R&D Center (Source: Ganfeng)

During China’s All-Solid-State Battery Innovation and Development Summit Forum earlier this month, company officials announced they had developed a “zero-strain” lithium alloy anode and a sulfur cathode that improves both electrochemical and thermal stability while preventing unwanted lithium movement.

According to the report, the lithium alloy anode expanded by just 3% to 5% during a full charge and discharge cycle, and passed both the nail penetration and heating test, surviving temperatures as high as 250°C (482°F).

(Source: Autohome)

(Source: Autohome)

Ganfeng put over 500 small-scale samples through its high-throughput screening process, with 20 reportedly making it to mass production.

The lithium-metal giant is also advancing all-solid-state batteries, which are now at the sample stage. Ganfeng said at the event that “we hope that our efforts in lithium alloy anodes can contribute to the industrialization of high-energy-density all-solid-state batteries.

Electrek’s Take

Ganfeng’s “zero-strain” lithium alloy anode is the latest in a series of breakthroughs and recent developments in solid-state EV batteries.

Earlier this month, China’s FAW Group said it had installed the “industry’s first” lithium-rich manganese semi-solid-state EV battery in a vehicle. The company said that the cell energy density tops 500 Wh/kg, while the total battery pack capacity is 142 kWh, unlocking over 1,000 km (620 miles) of CLTC range.

While Ganfeng’s semi-solid-state batteries are not currently used in passenger EVs, it’s likely not long before they are, given that the new tech is already in mass production.

Several major automakers and battery manufacturers, including BYD, CATL, Volkswagen, Toyota, Mercedes-Benz, and more, are planning to begin producing solid-state batteries on a small scale around 2027 or 2028, with mass production closer toward the end of the decade.

While solid-state batteries are often called the “holy grail” of EV battery tech, promising considerably higher energy density, longer driving range, and faster charging, they are only one part of the puzzle.

Lithium iron phosphate (LFP), sodium-ion, and other batteries are proving to be lower-cost, safer, and longer-lasting.

One thing is certain: Electric vehicles will continue to get more efficient, safer, more affordable, and will last longer as new battery tech enters the mainstream.

Source: CarNewsChina, Autohome

FTC: We use income earning auto affiliate links. More.