Ford’s upcoming $30,000 electric pickup is being designed to be the most energy efficient pickup ever built and the automaker is now revealing some of its secrets.

The Ford Maverick-sized pickup will be the first built on Ford’s new Universal Electric Vehicle platform, which will underpin a variety of vehicles in the coming years. It features a low drag body, lightweight chassis and efficient motors.

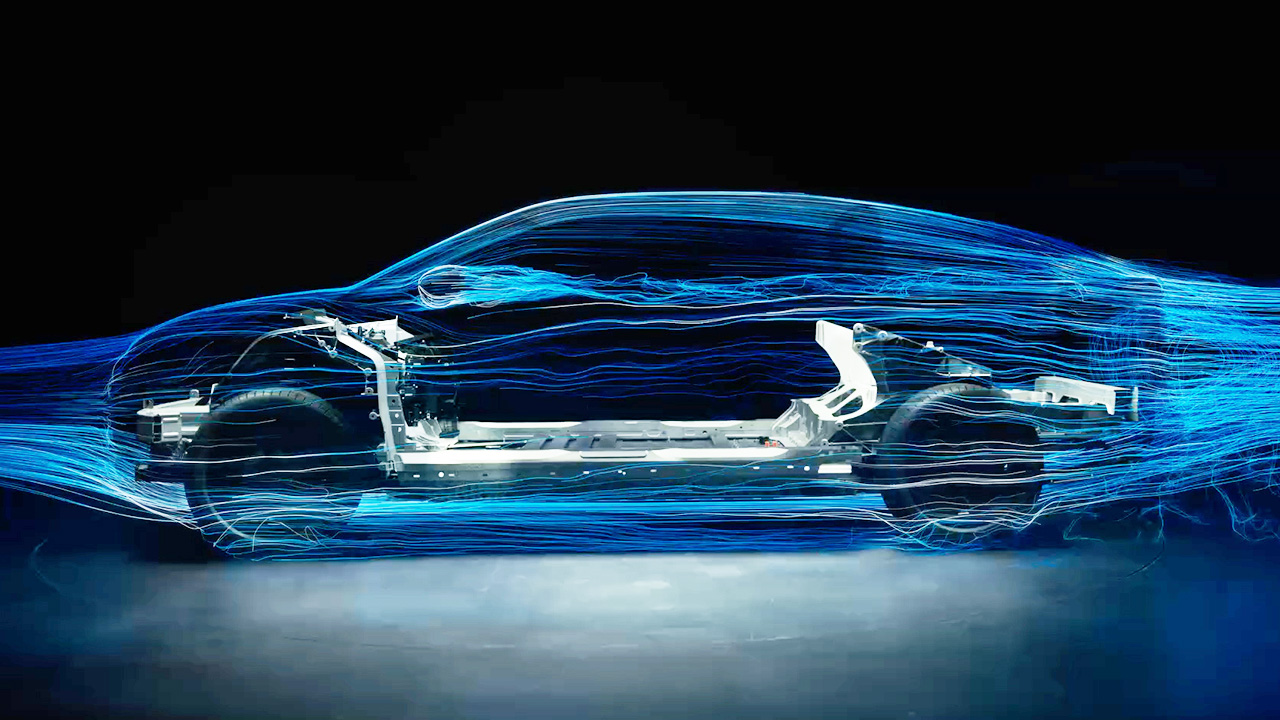

Images of the pickup in an aerodynamic streamline simulation reveal its basic outline. It features a rounded front end that appears to resemble the Mustang Mach-E’s and a relatively large cabin with a tapered roofline that directs airflow over the bed by creating a “virtual surface” that is similar in shape to a fastback.

“To the air, it is no longer a truck, but a sleek, aerodynamic silhouette,” Saleem Merkt, Advanced EV Aerodynamics Senior Manager explained in a blog post. Merkt said that more than half of his team is from the world of Formula 1.

Read Also: FORD’S $30,000 ELECTRIC PICKUP IS READY IF DEMOCRATS WIN BACK THE WHITE HOUSE AND CONGRESS

The vehicle also has sleek sideview mirrors that lower the aerodynamic drag enough to add 1.5 miles worth of driving range per charge, smooth underbody components and elements that “hide” the rear tires within the wake of the front tires.

(Ford)

(Ford)

Merkt said swapping this body onto a similarly sized Ford Maverick would result in a 15% overall improvement in fuel efficiency, rising to 30% at highway speeds.

(Ford)

(Ford)

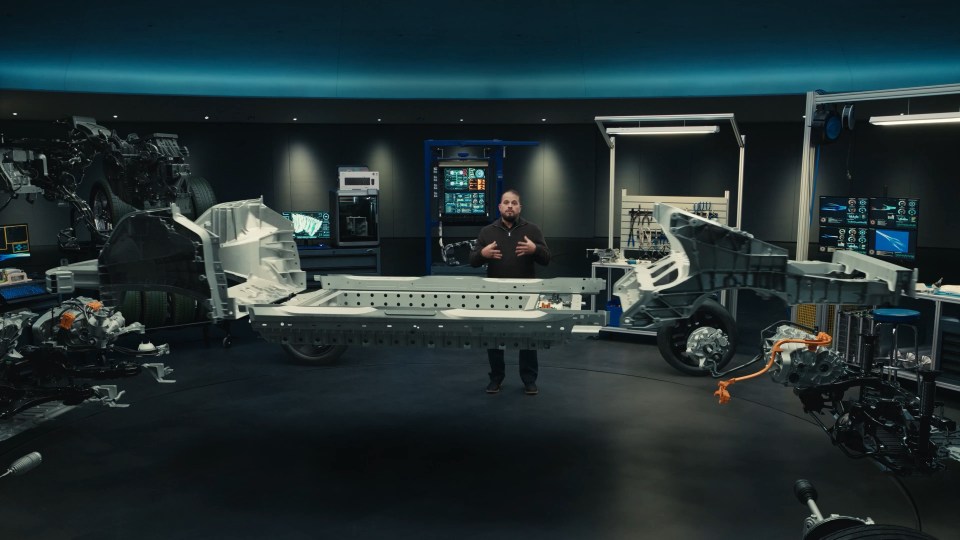

The chassis leverages that with weight reduction techniques that include the use of two large “unicastings” for the front and rear subframes that replace the 146 parts that would be needed for a conventional construction. They attach to the central frame and are 27% lighter than the ones pioneered by Tesla, according to Ford.

(Ford)

(Ford)

The central frame also houses the battery pack, which is comprised of low-cost and durable LFP (Lithium Iron Phosphate) prismatic cells that don’t require nickel or cobalt in their construction. The electrical architecture was developed in-house with simplicity in mind and Ford was able to cut the number of electronic control units from 30 to five while also trimming the wiring harness by 4,000 feet and 22 pounds.

Ford will announce the capacity of the battery, the vehicle’s range and other specifications closer to when it enters production in 2027, but said it will be able to accelerate to 60 mph in the four-second range.

SUBSCRIBE AND LISTEN TO THE GAS: AN AMERICAN CARS AND RACING PODCAST ON YOUR FAVORITE PLATFORM

Like this:

Like Loading…