E-bikes and automobiles share important commonalities: both are wheel-based forms of transportation, and both use microprocessors, batteries, and motors. “But despite these commonalities there has been an enormous difference in the marketplace performance of autos and e-bikes: while automobiles have enjoyed rising prices, frequent innovations, and sustained growth, for the past four years e-bikes have suffered declining prices, me-too product features, and lack of innovation: a perfect recipe for marketplace woes,” says John Hamann, CEO at Velocomp.

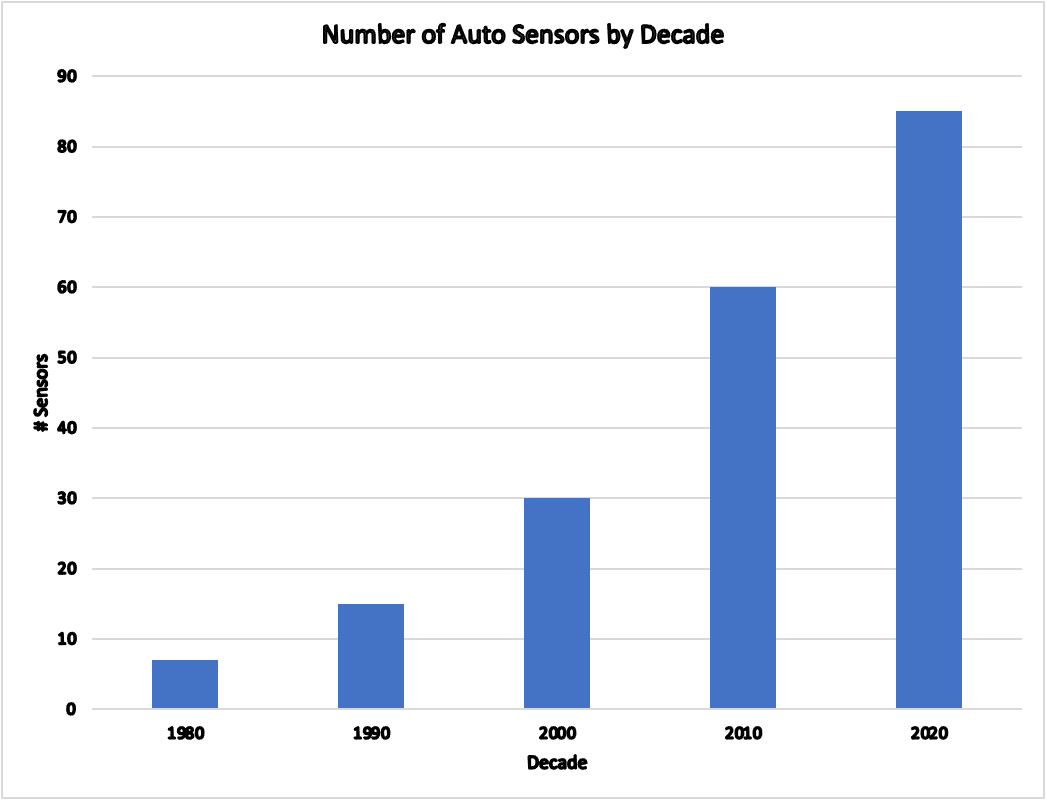

How have auto manufacturers achieved their product innovations? “One possible answer might be ‘faster microprocessors’, but that is not the correct answer,” says Hamann from Velocomp. “Microprocessors process information thousands of times per second, but a microprocessor’s ‘smarts’ is limited to the information it processes—and that information comes from sensors. In the 1980s cars used around 10 sensors, focusing mostly on basic engine management functions like temperature, pressure, and speed monitoring. Since then, sensor usage has roughly doubled each decade, enabling better performance, safety, and features. Today, most cars have nearly 100 sensors.”

Sensor proliferation

While other factors such as software advancements and computing power play a role in achieving higher performance and higher featured autos, the foundational enabler of improved automobile performance has been sensor proliferation, providing more and more data to microprocessors. Hamann: “Contrast sensor proliferation in autos to sensor stagnation in e-bikes. Today’s core e-bike sensors measure bike speed, cadence, and motor power; on more expensive e-bikes, a torque sensor measures pedal power. Some might argue that an e-bike brake switch is a sensor, but that’s like saying an on/off switch is a sensor. No matter how you count, e-bikes of 20 years ago had nearly the same array of sensors as those today. E-bike manufacturers have not followed the sensor proliferation/feature innovation path of auto manufacturers.”

Five major design philosophy differences

According to Hamann, it is readily apparent that there are five major differences in design philosophy between sensors used in automobiles and those used in e-bikes:

Auto manufacturers have strategically deployed additional sensors to improve car performance, enable new features, differentiate models and brands, and deliver more value to customers. With the exception of a torque sensor, core e-bike sensors do not significantly improve e-bike performance, add new features, or differentiate e-bike models and brands.

Automotive sensor usage has roughly doubled every decade, yet the number of sensors used in e-bikes has remained nearly unchanged. While it’s unlikely that e-bikes can copy the high growth rate of auto sensor adoption, there is substantial opportunity to improve e-bike performance by using more sensors.

Automobile sensor technologies have improved enormously and costs have dropped; e-bike sensor technologies are almost unchanged and costs remain high, particularly for the torque sensor.

Sensor fusion, the combining of various sensor data in AI-like microprocessor algorithms to create new performance and feature enhancements, is common in automotive applications but is essentially non-existent in e-bikes.

Automotive companies have controlled the design, timing, and marketing of sensor innovations. Sensor-based e-bike features such as radar, tire pressure, and GPS, have primarily come from add-on accessories made by third-parties, outside the control of the e-bike manufacturer.

New Sensors for e-bikes

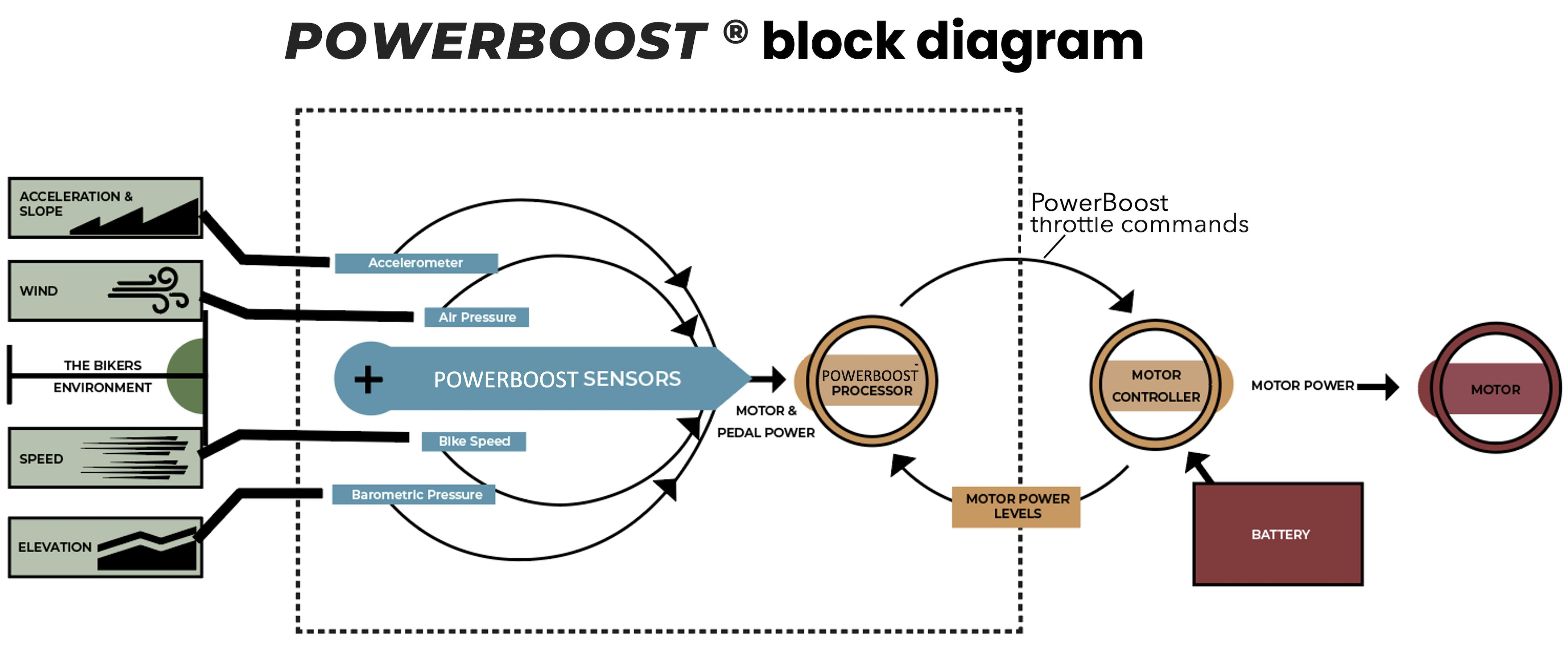

“Applying auto sensor strategies to e-bikes include four elements: adding new sensors to e-bike designs, focusing first on core e-bike attributes such as motor response; replacing legacy e-bike sensors with lower cost alternatives; creating algorithms that combine sensor data to deliver new, premium features; customizing e-bike performance by model/brand through proprietary microprocessor algorithms,” says Hamann. Velocomp LLC has applied all these principles in its new PowerBoost system for e-bikes.

Velocomp has extensive experience in deploying sensor innovations in cycling. The company disrupted the power meter category 21 years ago with its innovative, patented combination of accelerometer, air pressure, and speed sensors, reducing the opening price point of bicycle power meters from $1,500+ to $299. Hamann: “Our sensor data also enabled a generation of subsequent cycling innovations including left/right leg balance, drafting detection, and aerodynamic drag measurement, all based on firmware algorithm enhancements, without additional BOM cost.”

PowerBoost system

Velocomp’s sensor innovations have now been implemented for e-bikes in a newly patented system called PowerBoost. “Accelerometer and air pressure sensors provide accurate, real-time environmental data including wind speed, hill slope, and bike acceleration. PowerBoost algorithms combine them to measure the total power opposing the forward motion of the e-bike. Measured motor power, subtracted from the total opposing power, yields pedal power—the same pedal power measured by expensive torque sensors. PowerBoost achieves torque sensor performance without using a torque sensor,” says Hamann.

Benefits

Torque sensor performance is not the only advantage achieved by PowerBoost sensors and algorithms, says Hamann. “PowerBoost’s reliable, solid-state sensors are produced in very high volumes for smartphone and industrial applications, making it possible to deliver torque sensor performance at a cost savings of $20-$40 per unit. Additionally, PowerBoost requires no factory-floor installation and calibration, eliminating the time and cost associated with installing and calibrating torque sensors. The system’s handlebar location allows the same HMI to be used across any e-bike design. PowerBoost adjusts motor output dynamically, 20 times per second, to changes in slope, wind speed, and bike acceleration conditions, making e-bike pedaling just like ‘normal’ pedaling, but easier.”

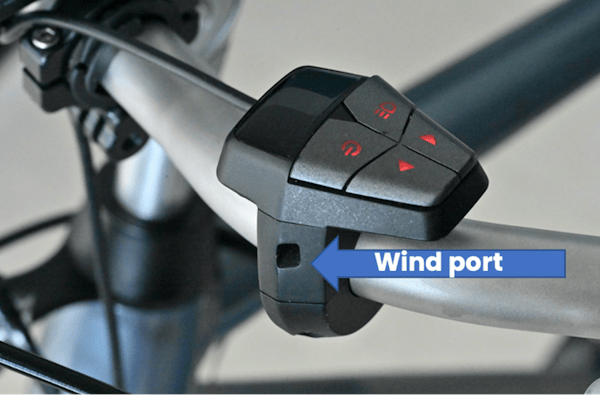

It also modifies the motor’s starting torque based on the slope, increasing torque on steeper inclines to make starting easier, says Hamann: “For cargo bikes, PowerBoost can automatically detect the weight of the load being carried, adjusting the motor’s output accordingly and displaying the weight on the HMI. The system also optimizes battery usage by automatically engaging recuperation mode, allowing for efficient recharging. Because PowerBoost continuously measures environmental data, real-time information about slope and wind speed can be displayed on the HMI, providing cyclists with better insight into their current riding conditions. Additionally, the performance and behavior of the e-bike can be customized through proprietary firmware updates in the HMI, offering flexibility for different models or brands. Lastly, PowerBoost’s sensors are located on the handlebar HMI, protected from rain and water splashes that often affect torque sensor seals, reducing the need for costly repairs caused by seal failures.”

PowerBoost is ready-for-market

AVS Mobility, long-time partner of Velocomp, has implemented PowerBoost sensors and technology in its ‘RC’ line of HMI displays. Hamann: “Starting at around $40, AVS handlebar-mounted HMIs provide conventional e-bike control and all PowerBoost functionality. Integrated Bluetooth also allows setup and control from any smartphone, over-the-air firmware updates, and real-time display of environmental data including slope and wind speed. W-bike manufacturers can further customize the performance of any RC HMI through simple firmware modifications.”

This article is sponsored by Velocomp.