For nearly a decade, the “skateboard” chassis has been the undisputed king of electric vehicle (EV) design. From Tesla to Rivian, the formula was simple: a flat battery pack at the bottom, motors on the axles, and a body bolted on top. It was hailed as the ultimate in efficiency. But Toyota, the company that practically invented modern manufacturing, has just signaled that the skateboard’s reign is over.

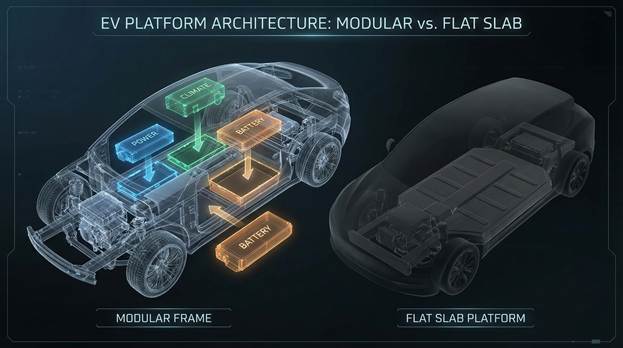

New patent filings and internal strategy shifts reveal that Toyota is moving toward a modular “box” architecture. This isn’t just a slight tweak to the frame; it is a fundamental reimagining of how a car is built, maintained, and evolved. By placing critical components into standardized, replaceable “boxes” rather than integrating them into a rigid floorboard, Toyota is preparing to outmaneuver both the design limitations of current EVs and the aggressive pricing threats coming out of China.

Breaking the Board: Why the Skateboard is Failing

The skateboard chassis was a great “Version 1.0” for the EV era. It lowered the center of gravity and cleared out the engine bay. However, it created a new problem: packaging rigidity. In a skateboard design, the battery is often a structural member of the car. While this is great for crashes, it’s a nightmare for repairs. If a single section of the battery or a cooling line fails, you often have to drop the entire thousand-pound assembly, leading to astronomical repair bills.

Toyota’s new approach moves away from this “monolithic” philosophy. Instead of a single slab, the chassis is treated as a grid where functional modules—power electronics, battery clusters, and climate systems—sit in dedicated “boxes.”

The Modular Advantage: Better for Drivers and Makers

The shift to a modular “box” design offers two massive wins: manufacturing agility and long-term ownership value.

For the manufacturer, modularity allows for “late-cycle” changes. In a traditional line, once the chassis is set, you are locked in. With a box system, Toyota can swap a battery module for a newer Solid-State battery version or upgrade a power inverter without redesigning the entire undercarriage. This allows Toyota to react to technological leaps in months rather than years.

For the driver, this is the end of the “disposable car” era:

Cheaper Repairs: If a power module fails, a technician can simply swap that specific “box.” This mirrors the logic of the Toyota Production System (TPS), which emphasizes efficiency and waste reduction.

Interior Freedom: By moving components into specific zones, Toyota can achieve a “flat floor” that is truly flat, pushing wheels further to the corners. This is already evident in their concepts like the Toyota e-Palette, which utilizes this philosophy to maximize cabin volume.

The “China Shield”: Lowering Costs Through Standardization

Toyota isn’t just doing this for the sake of cool engineering; it’s a survival tactic. Chinese automakers like BYD and Xiaomi are leveraging massive scale to drive prices down. Toyota’s response is radical standardization.

By creating “boxes” that are common across the entire Toyota and Lexus lines—and potentially sharing them with partners like Subaru and Mazda—Toyota creates an economy of scale that is virtually unbeatable. Imagine a world where a Corolla EV and a Lexus crossover use the same standardized steering and power modules. This “Lego-fication” of the car reduces R&D costs and allows Toyota to compete in the low-margin segments where China currently dominates.

Design Flexibility and the “Short-Run” Revolution

One of the most exciting side effects of going modular is the impact on design flexibility. Because the “guts” of the car are tucked away in standardized boxes, the “top” of the car (the “upper body”) can be almost anything.

This paves the way for “short-run” automobiles—niche vehicles produced in small numbers for specific lifestyles—without the billion-dollar overhead usually required. It also opens a massive market for car accessories. Imagine buying a “camping box” that plugs into your chassis to provide extra battery life and outdoor power, similar to the modularity seen in the Toyota IMV 0 platform recently launched in emerging markets.

Learning from the Past: Will it Work?

History is littered with attempts at modularity. In the early 2000s, GM teased the “Autonomy” concept, which promised a similar swappable body system. It failed because the technology—specifically drive-by-wire—wasn’t ready.

However, Toyota is building on the success of the Toyota New Global Architecture (TNGA), which already standardized parts to improve vehicle performance. Unlike GM’s 20-year-old dream, Toyota’s modular boxes utilize current Giga-casting technology, making the manufacturing of these modules faster and more cost-effective than ever before. Given Toyota’s history of perfecting manufacturing through “Kaizen” (continuous improvement), this move is highly likely to succeed where others failed.

Toyota’s Fortunes: A Bright Future

Toyota is currently in a position of strength, reporting record-breaking financial results even as competitors struggle with the EV transition. By moving away from the rigid skateboard design, they are insulating themselves against the rapid obsolescence of battery tech.

This move will improve Toyota’s fortunes by turning the car from a static product into a dynamic platform. It ensures that Toyota remains the “gold standard” for reliability, as a car that is easier to repair and upgrade will naturally hold its value longer than a monolithic EV with a non-serviceable battery.

Wrapping Up

Toyota’s pivot from the skateboard chassis to a modular “box” design marks a turning point in automotive history. By prioritizing repairability, interior space, and extreme standardization, Toyota is addressing the two biggest complaints about EVs: high repair costs and “same-y” designs. This move not only streamlines their global production but also provides a robust strategy to underprice competitors while offering more value to the consumer. If successful, the “box” will do for the 21st century what the assembly line did for the 20th—make the automobile more accessible, adaptable, and enduring than ever before.

Disclosure: Images rendered by Artlist.io

Rob Enderle is a technology analyst at Torque News who covers automotive technology and battery developments. You can learn more about Rob on Wikipedia and follow his articles on TechNewsWord, TGDaily, and TechSpective.