After waiting for nine long years, the Tesla Semi, an all-electric truck, is finally out of the pre – production limbo.

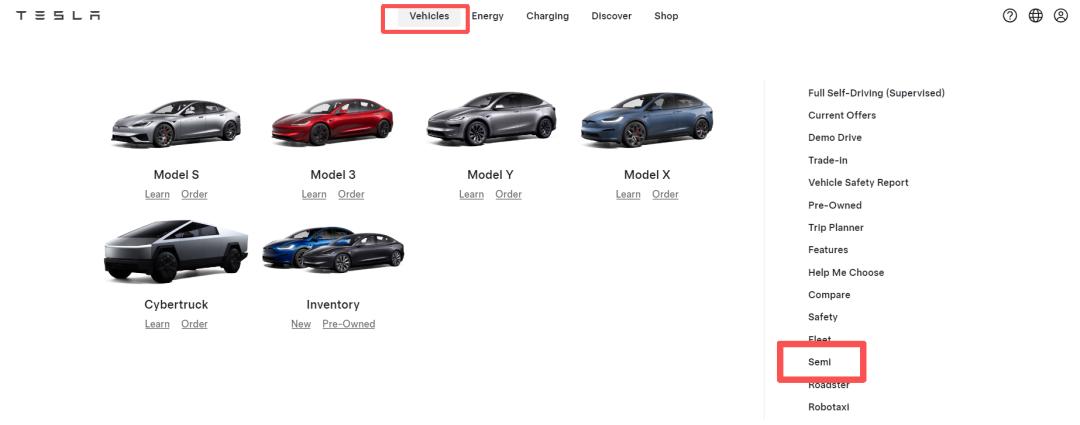

As soon as the new factory was recently completed, Tesla announced the new specifications of the Semi on its official website, indicating that mass production is just around the corner.

The standard – range version can travel up to 523 kilometers on a single charge, exceeding the initial 483 – kilometer range advertised nine years ago. Its energy consumption is 1.06 kWh per kilometer, lower than the original plan.

However, with the upgraded features comes a higher price. The price of the new vehicle was later exposed: $290,000 per truck, which is approximately 2 million RMB.

The state of California in the United States immediately stepped in to show its support by issuing purchase vouchers for the Semi, with a total value of $165 million (about 1.14 billion RMB).

Tesla Reveals Specifications of All – Electric Truck

Recently, Tesla updated the “Semi” page in its official vehicle options, suggesting that the mass production and delivery of the Semi are on the agenda.

On the new interface, Tesla divides the Semi into the Standard Range and Long Range versions and updates the latest production specifications of the two models.

Both versions are equipped with three independent motors on the rear axle, with a maximum driving power of 800 kW. Their unified energy consumption is 1.7 kWh per mile, which is approximately 1.06 kWh per kilometer.

Meanwhile, both versions support the MCS 3.2 charging standard (a megawatt – level high – power charging standard specifically for large vehicles such as electric heavy – duty trucks). After a 30 – minute charge, they can replenish up to 60% of their range.

The vehicle also adds new information about electric power take – off (ePTO), with a maximum of 25 kW for both versions. It also reserves an interface for autonomous driving.

Among the known parameters, the biggest differences lie in the range and the curb weight:

The Standard Range version has a range of 325 miles (about 523 kilometers) and a curb weight of less than 20,000 pounds (about 9.07 tons), making it more suitable for medium – and short – distance or urban distribution scenarios.

The Long Range version can travel up to 500 miles (about 805 kilometers) on a single charge, with a curb weight of 23,000 pounds (about 10.43 tons), making it more suitable for long – haul transportation.

Compared with the concept first proposed in 2017, the parameters updated this time have been slightly adjusted.

First of all, the range of the Standard Range version has increased. The originally envisioned ranges of the two versions were 300 miles (about 483 kilometers) and 500 miles (about 805 kilometers) respectively.

Secondly, the current energy consumption is also lower than before. In 2017, the value was 2 kWh per mile (about 1.24 kWh per kilometer), which means that the actual cost per mile has further decreased.

Another change is the motor. Previously, the plan was to use four independent motors to emphasize extreme performance. Now, one motor has been removed, simplifying the structure and reducing the manufacturing cost.

In addition, there are also slight differences in appearance.

The front bumper has been redesigned with the addition of aerodynamic air ducts. The area of the windshield has been significantly reduced, and its coverage has also been shrunk.

The roof line is more rounded and smooth, and the transition between the side skirts and the wheel arches is more optimized. This is also to further reduce the drag coefficient and energy consumption.

In 2017, Elon Musk announced that the starting price of the 300 – mile range version was $150,000 (about 1.037 million RMB), and the starting price of the 500 – mile range version was $180,000 (about 1.244 million RMB).

Now, with a series of upgrades in the new version and the passage of many years since the initial concept was proposed, according to Tesla’s past style, the price of the Semi is likely to be higher than the early publicity.

According to foreign media Electrek, informed sources have obtained the price information. The current price of the Long Range version of the Semi is $290,000 (excluding destination fees and taxes), which is approximately 2 million RMB, about 61% higher than the price nine years ago.

However, according to statistics from the California Air Resources Board, compared with electric semi – trucks of the same class in the United States, Tesla’s price is still significantly lower than the industry average ($435,000).

It seems that the Semi may really be on the verge of mass production and delivery.

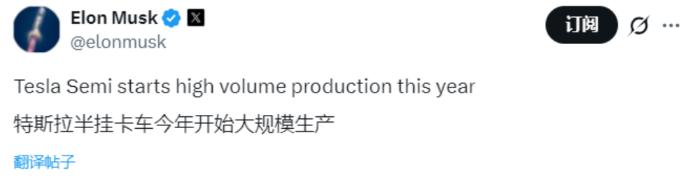

Elon Musk also recently confirmed on social media that Tesla’s semi – trucks will start mass production this year.

Is the long – awaited Semi still in time?

Mass Production Has Been Delayed for 7 Years

The concept of the Tesla Semi was first announced in November 2017, with a plan to start formal production in 2019.

At that time, Tesla’s core mission was “to accelerate the world’s transition to sustainable energy”.

Trucks, especially heavy – duty trucks, have always had a problem of high fuel consumption and low electrification penetration at that time.

According to a research report by IHS that year, although heavy – duty trucks only accounted for a small part of the world’s vehicles, their oil consumption was roughly equivalent to that of small cars, accounting for about one – fifth of the world’s total oil consumption.

The electrification of trucks is of great significance to energy transformation. It is also a huge market worth tens of billions of dollars annually. For Tesla, entering the heavy – duty truck market is a crucial step in its expansion into the commercial vehicle field.

According to the original concept, the total cost of ownership of Tesla’s electric trucks over their entire life cycle would be much lower than that of diesel trucks, and their energy cost might be only one – third to one – half of that of diesel trucks.

Strategically, Elon Musk set the “Second Master Plan” in 2016, and the Semi is an important part of the plan to “cover the major ground transportation systems”.

Moreover, Tesla’s accumulated experience in battery, motor, and electronic control technologies, as well as its autonomous driving technology, can be directly applied to the heavy – duty truck field, providing more efficient and cost – effective tools for fleet operators.

However, despite the beautiful concept proposed many years ago, the delivery time of the Semi has been continuously postponed, and there have been more difficulties than expected.

The most core obstacle lies in the battery.

To enable heavy – duty trucks to carry more and travel farther, a huge battery pack is required, which directly drives up the cost and vehicle weight. It takes time to optimize battery technology and management systems.

One of the keys to cost – reduction for the Semi is the use of Tesla’s self – developed 4680 battery. As we all know, due to bottlenecks in the dry – electrode process of the battery, the supply of the 4680 battery has never been able to keep up.

Another major challenge is charging. Heavy – duty trucks require megawatt – level (MW) ultra – fast charging to replenish energy within a reasonable time.

However, building this dedicated charging network is a huge engineering and capital challenge, so the construction of megawatt – level charging stations has been relatively slow.

Therefore, there have always been doubts about the feasibility of achieving a large – capacity battery and an ultra – fast charging network.

Even when Bill Gates visited the Tesla factory, he directly told Elon Musk that all – electric long – haul semi – trucks “won’t work”.

However, Elon Musk replied, “We already have them. You can drive one yourself.” He also revealed that PepsiCo, a food and beverage giant, is using the Semi trucks.

In fact, PepsiCo was one of the first customers of Tesla’s Semi trucks, receiving the delivery in 2022 – three years later than the original plan. It can be said to be one of Tesla’s most long – awaited vehicles.

In addition, DHL, a German logistics giant, is also a customer of the Semi. DHL also confirmed to the media that its trucks operate in California every day, traveling about 100 miles (about 161 kilometers) per day and needing to be charged about once a week.

Some netizens also said that they have actually seen the Semi:

There is even a Semi (PepsiCo version):

Moreover, another problem plaguing the Semi is production capacity.

After 2017, Tesla was deeply trapped in the “production hell” of the Model 3. It had to prioritize resources and production capacity for this “high – volume model”, and the progress of the Semi had to be postponed. It was not until the Shanghai Gigafactory started production in 2020 that Tesla’s production capacity pressure was relieved.

Now, the upcoming launch of the mass – producible version of the Semi means that the biggest problem before has been gradually solved.

This also coincides with Tesla’s recent developments –

The 4680 battery has overcome the final technical bottleneck and has started production. It has been installed in some Model Y vehicles, and production will continue to expand in two major factories this year.

The Semi – dedicated factory in Nevada, USA, began construction in 2024 and was nearly completed by the end of 2025. According to Tesla executives, the Semi trucks are currently in trial production at the factory.

When the factory is operating at full capacity, its annual output can reach up to 50,000 vehicles.

![‘Hard to believe now that [this] came out over 10 years ago’ 'Hard to believe now that [this] came out over 10 years ago'](https://www.evshift.com/wp-content/uploads/2026/02/40dfb6de6ca4621c76e5e8ed6e87d384-770x515.jpeg)