IM Imagery/Shutterstock

EVs (Electric Vehicles) of all types are quickly becoming more popular, and public policy is changing as quickly as the technology behind them. New Jersey now requires e-bike riders to be licensed and insured, and some Verge motorcycles are now equipped with new solid-state battery tech from Donut Lab. This phone-sized battery packs four times the watt-hours per kilogram as the battery in a Tesla Model 3, and Donut claims it can be charged from 10% to 80% in just five minutes and will last for 100,000 charge cycles.

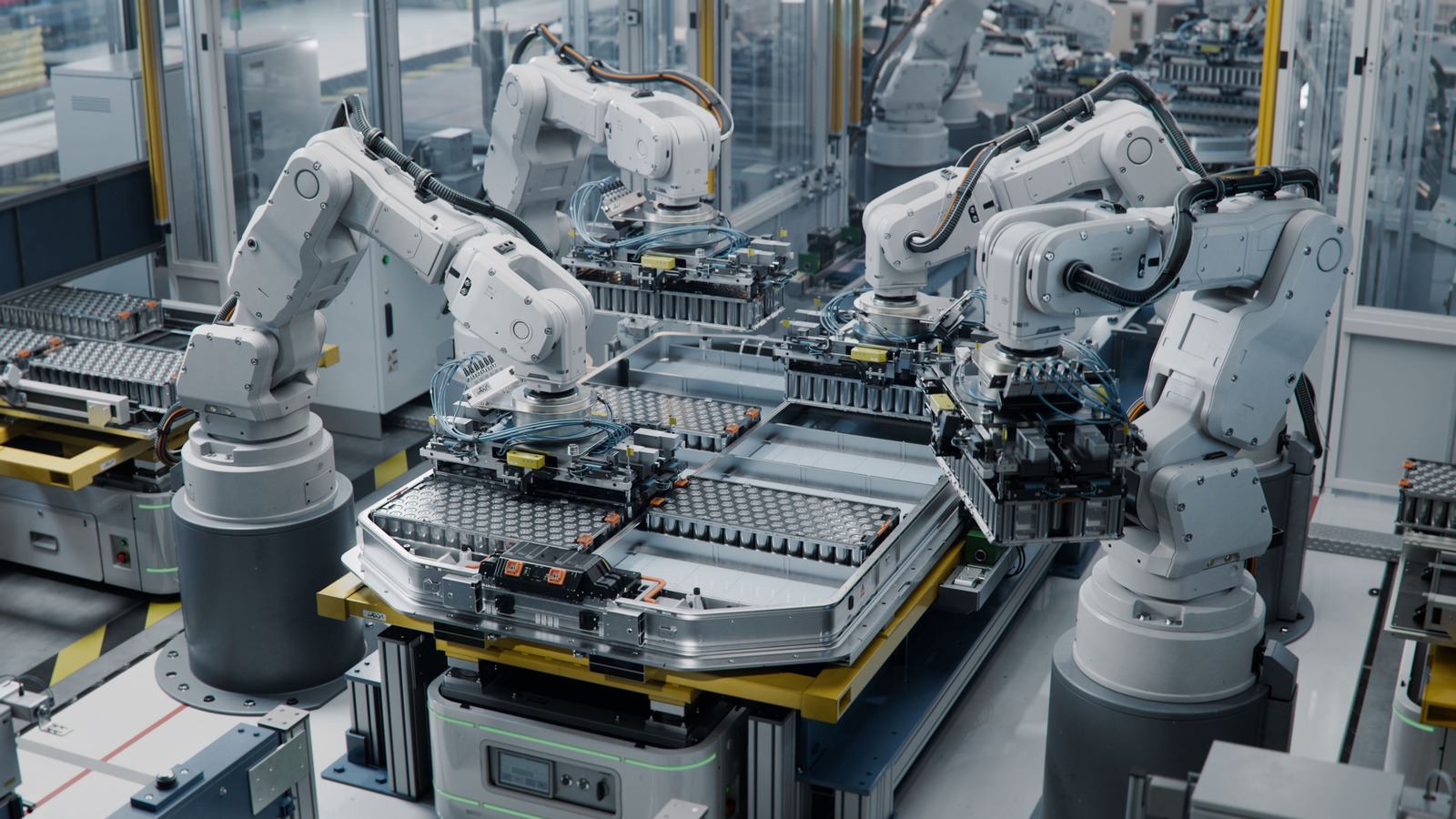

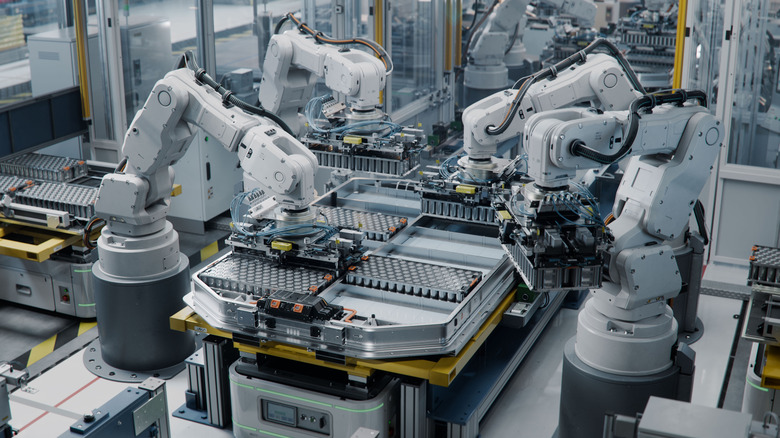

Solid-state batteries are also less prone to thermal runaway than the lithium-ion cells used in most current EVs, which could help prevent the garage fires that make national news every time they happen. Charging concerns are the biggest obstacle to widespread adoption of EVs, so it also stands to reason that potential electric car buyers might be curious about solid-state batteries. Global automotive giants like Toyota, Volkswagen, and Ford are reportedly working on the technology, but as of this writing, you can’t buy an electric car with a solid-state battery from those or any other U.S-market automaker. Because the technology is so new and only in production by a handful of European companies like Donut and a few Chinese rivals, the manufacturing process isn’t yet developed enough to produce them at the scale needed to support the global auto industry.

Solid-state batteries are still too new for mass production

Thx4Stock team/Shutterstock

Unlike traditional liquid-electrolyte batteries, solid-state batteries use a gel made of ceramics, polymers, or sulfides to facilitate the flow of charged ions through the battery.

While the manufacturing infrastructure isn’t sufficient for large-scale production at this point, the promised performance and safety gains are enticing enough to have companies throwing money and research in that direction. Stellantis is partnering with Factorial Energy on solid-state batteries for its vehicles, and in April 2025, the global automotive group announced plans to use the tech in a fleet of demonstration vehicles by the end of 2026. The Factorial Electrolyte System Technology (FEST) battery will perform similarly to the Donut one, with an energy density of 375 Wh/kg and a charging time under 20 minutes.

As more solid-state EV batteries are produced — even for demonstration and testing purposes — the manufacturing process will get faster and cheaper, meaning production should be able to increase with the inevitable demand. What is now a niche technology could become commonplace in a few years; Mercedes, BMW, and Rimac are all planning to use solid-state batteries in their EVs. There’s been another important breakthrough outside the automotive industry. A 2023 Motor Trend report noted that a 3D printing startup in California had developed a fast, efficient way to make solid-state batteries, so it’s likely only a matter of time until 3D printers are in use on auto assembly lines. With advancements coming so quickly and plenty of market momentum for EVs, it’s only a matter of time before solid-state batteries power the world’s electric cars.