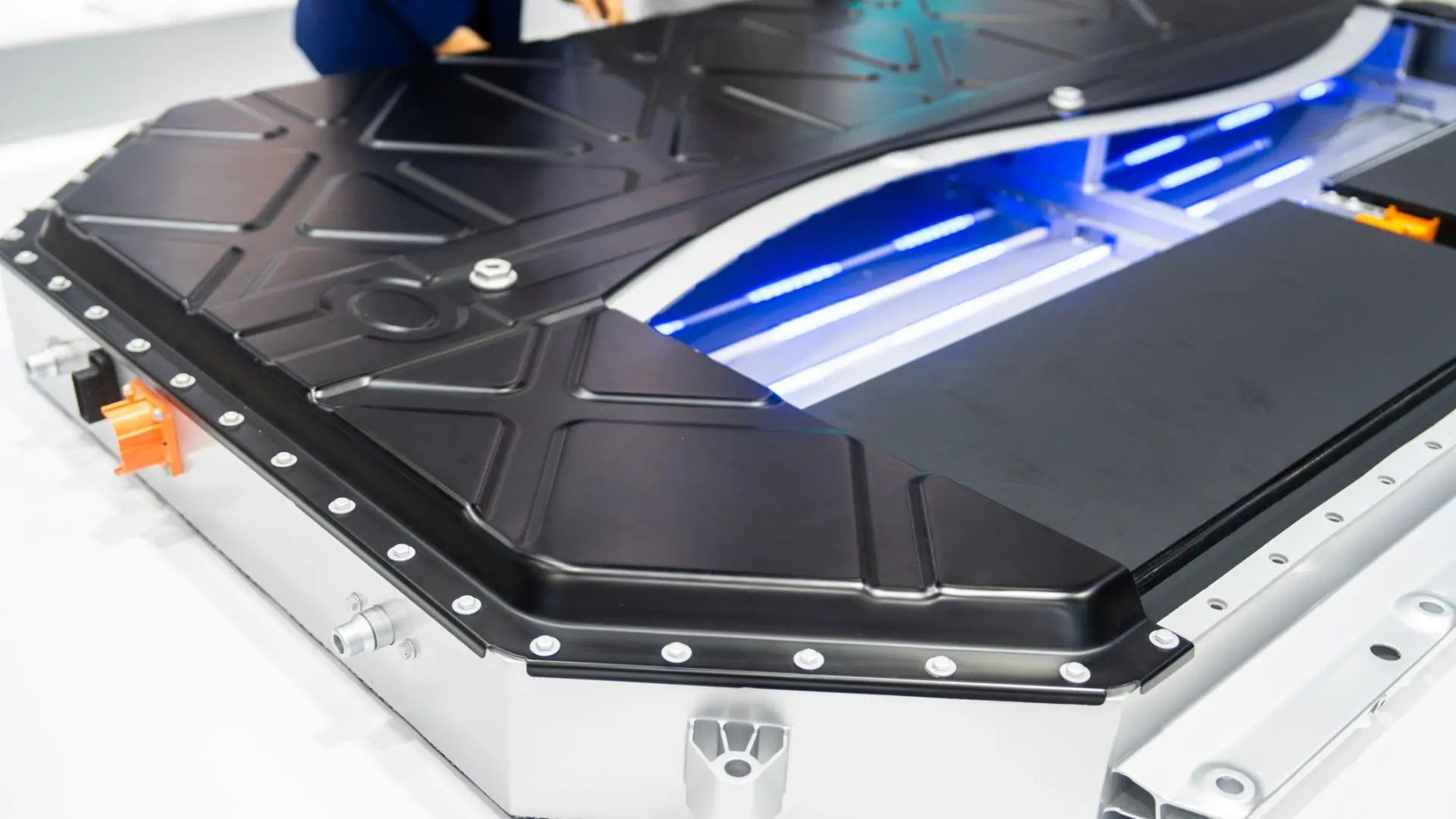

A battery research team in South Korea has reported a breakthrough that could help electric vehicles go farther without losing punch during hard acceleration.

The researchers affiliated with the Ulsan National Institute of Science and Technology announced a newly designed thick electrode that delivers much higher power while keeping high energy storage.

The work, led by Professor Kyeong Min Jeong, addresses a long-standing tradeoff in battery design.

Tackling the range versus power problem

Automakers are under pressure to extend driving range, and one direct way to do so is to increase the amount of active material in battery electrodes. This approach creates thicker electrodes that can store more charge. The downside is that the power output usually drops.

Lithium ions have to travel longer and more complex paths, which slows discharge and hurts performance during demanding conditions such as climbing hills or quick acceleration.

The UNIST team focused on this exact bottleneck. Their goal was to keep the benefits of thick electrodes while restoring lost power. By rethinking how ions move through the electrode interior, the researchers found a way to significantly reduce resistance without sacrificing capacity. The result is a design that supports long-range driving while maintaining strong, responsive power delivery.

Power gains from pore-level engineering

The key advance came from optimizing the internal pore structure of the electrode. Inside a thick electrode, not all pores behave the same way. Some are relatively large gaps between active material particles that allow lithium ions to move easily. Others are much smaller and are created by conductive additives and binders. These tiny spaces form what is known as the carbon-binder domain, or CBD.

The team showed that while the CBD is essential for moving electrons, it can also block ion transport if it becomes too dense or uneven. In thick electrodes, this effect becomes more severe. By carefully adjusting the balance and distribution of these pores, the researchers were able to open faster ion pathways while preserving electronic conductivity.

This structural tuning led to a clear performance jump. The electrode maintains a high areal capacity of 10 milliampere-hours per square centimeter. Under a demanding 2C discharge rate, it delivered 1.71 mAh per square centimeter, compared with 0.98 mAh per square centimeter from a conventional thick electrode. That represents about a 75 percent increase in short-burst energy output.

A new model to guide electrode design

To reach this result, the team went beyond trial-and-error manufacturing. They developed a new analytical framework called the Dual-Pore Transmission Line Model, or DTLM. This model separates ion movement into two parallel pathways that reflect the behavior of large pores and CBD-related micropores.

Traditional models tend to average porosity into a single value, which hides critical details. DTLM instead links electrical resistance directly to physical features inside the electrode. Using this approach, the researchers could pinpoint how CBD content, particle clumping, and binder ratios affect ion flow and stability. That insight allowed them to fine-tune processing steps and material proportions with much greater precision.

“Having a quantitative way to analyze these structures provides a solid foundation for applying advanced AI techniques, like physics-informed neural networks, to battery design—even when data is limited,” explained first author Byeong-Jin Jeon.

Implications for future EV batteries

Professor Jeong emphasized that the findings extend beyond one battery chemistry.

“As we move toward thicker electrodes, it is not just about the materials themselves, but also how we design and manipulate their microstructures. Our work offers valuable insights not only for high-nickel batteries but also for other next-generation chemistries, like lithium iron phosphate (LFP), where controlling the internal structure is particularly important,” he added.

For electric vehicles, the impact could be significant. Batteries built with this approach could maintain strong power output even as capacity increases, supporting longer range without compromising performance.

The study was published in the journal Advanced Energy Materials.