Researchers have introduced a contactless electricity generation method using only practical compressed air and a Tesla turbine structure. This system achieves peak outputs of 800 V and 2.5 A at 325 Hz without requiring any additional particles leveraging electrostatic charges and the viscous force of compressed air.

Researchers revealed that the high-voltage output facilitates the neutralization and collection of dust and moisture by generating negative ions.

The research team claims that this integrated approach expands the practical potential of static electricity-based energy harvesting for industrial applications.

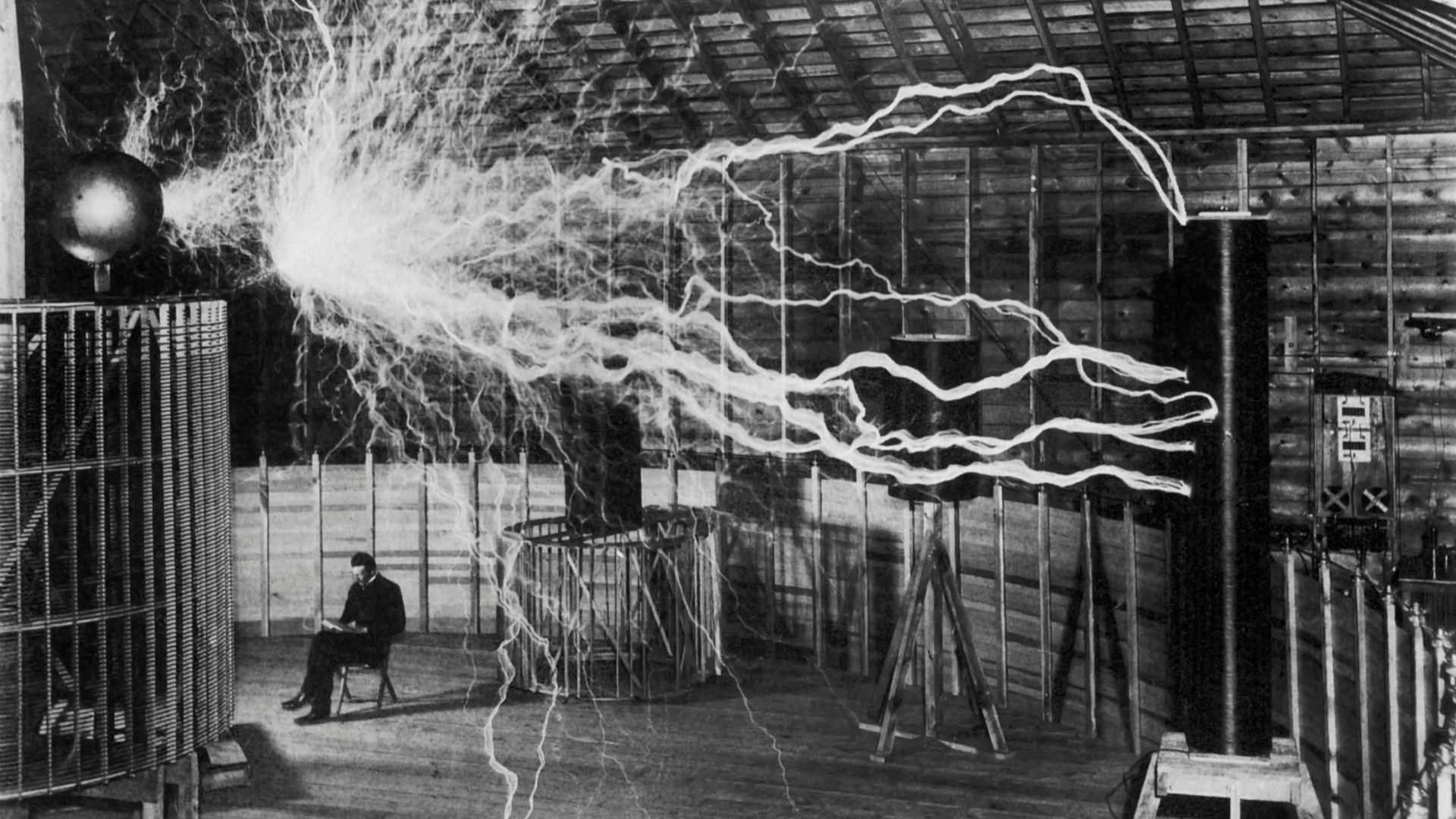

New system draws inspiration from the Tesla turbine

Reports have revealed that the new system draws inspiration from the Tesla turbine, a bladeless rotary design patented by Nikola Tesla in 1913. Unlike conventional turbines with angled blades that deflect fluid flow, Tesla’s elegant design uses viscous drag to spin smooth, closely spaced discs. Air clings to the disc surfaces and transfers momentum as it spirals inward.

The new device combines this century-old turbine concept with modern triboelectric materials. It consists of a rotating disc assembly, triboelectric layers made from opposing materials, bearings, and an acrylic housing. Compressed air enters through an inlet and creates a high-speed swirling flow reaching 300 m/s. This airflow spins the rotator through surface friction alone. At 0.2 MPa of pressure, the rotator achieves 8472 revolutions per minute, reported Nanowerk.

This technology could provide a dual-purpose solution to industrial facilities already using compressed air. Not only could it generate power, but it could also help neutralize static electricity, improving safety and air quality. The potential for lower energy costs and a safer environment is quite promising.

Harvesting static electricity in compressed air

The idea of harvesting static electricity in compressed air, which has long been a nuisance in industrial environments, presents an innovative approach to turn waste into usable energy while solving a significant safety problem. This blend of old (Tesla’s turbine) and new (triboelectric materials and modern electronics) could revolutionize how we view and utilize the forces present in everyday industrial processes.

Compressed air is used extensively in industrial environments due to its versatility and efficiency. It powers tools, machines, and automation processes in industries such as manufacturing, automotive, and robotics. However, as compressed air travels through pipes, it often carries tiny particles of dust and water molecules. As these particles collide with the inner surfaces of pipes, they can develop static charges. This phenomenon, known as the triboelectric effect, occurs when materials gain or lose electrons during friction.

Nikola Tesla’s bladeless turbine design relies on viscous drag rather than traditional blades to generate rotational motion. In a conventional turbine, blades are angled to deflect fluid flow and convert kinetic energy into mechanical work. In contrast, Tesla’s design features smooth, closely spaced discs that allow air or other fluids to cling to the surfaces of the discs and transfer momentum as they spiral inward. The absence of blades allows the Tesla turbine to operate with fewer moving parts, leading to greater durability and reduced mechanical wear.

The new technology described in the study demonstrates the incredible potential of combining classic engineering principles (like the Tesla turbine) with modern materials science to address long-standing industrial challenges. By capturing and using the static electricity in compressed air, this system offers a sustainable way to generate electricity while also neutralizing hazardous charges that pose safety risks. In doing so, it could not only revolutionize industrial power generation but also improve the overall safety and efficiency of industrial environments.