Electric car conversion, 1951 Shoebox body fit to Tesla unibody, SEMA 2025, body swap, custom build

[Music] Heat. Heat. [Music] All right, let me explain why why I went through all this trouble. Right here in the dash, uh right in here is where the new actual metal part of the dash is going to lay. So that’s the front of the car is right there or the front of the firewall. So all this is going to be in front of the firewall now. So having a dash and speakers and that kind of stuff there didn’t work. Having an airbag underneath the metal of the dash doesn’t work cuz if there’s an accident, boom, it explodes. just got nowhere to go. It’s going to go down. It’s going to go sideways. It’s going to blow the glass out. I don’t want any of that. So, it had to go. Now, why didn’t I just cut this and take it away and leave the bottom intact? Honestly, I didn’t know where everything was and there’s some wires and stuff right there. So, I’m I’m glad I didn’t cut it cuz I may have cut into those. The right thing to do was pull it out, cut it, and now we’re just going to put it back in. I mean, it’s really that simple. Um, but it’s going to give us some access to some things that we needed. The defroster or the recirculation. I’m not I think that’s defroster. I think re recirculation comes through the center console. I don’t know. I’m wrong. I don’t know. But it’s one or the other, but it’s got to be functional. I think it’s defroster cuz then that would came up into the bottom of the dash and the dash had vents to go out. So, I’m going to have to put something like that in this one. Um, airbags gone. I’m going to get all this stuff cleaned out of here. But I mean, that’s just that’s all that was. It was a lot of work for what seems like not much gain, but this piece here is going to sit right on top of that. So, that had to go. Now, I got to trim some metal, some posts, some things, and try to fit some metal. So, just so you understand what the heck I was doing. which we’re starting to make a fix on the trunk latch code, a chopped up dashboard, chopped up everything, and a very chopped up meteor. You can barely see it, but it’s just a skeleton here, which is all we need. That’s all we need to get started because I’m going to fit it. I’m going to make it look nice, people. This isn’t a The intent is not to be a hack job, right? I understand it’s kind of hack job looking. Well, it’s not hacked looking. It’s It’s hacked up, but the intent is to build a custom like, see, now I hate that I say like old school 60s, but that’s what I mean. is a 2025 version of 1950s or60s custom, you know, custom lights, everything, you know, chop top, all that kind of stuff. Smooth, all the stuff that’s got to happen to make this thing, you know, a custom. Right now, she’s a shell and it’s weird. It’s a trip. Um, but that’s what’s got to happen. I mean, really all we have are the door pillars, the Apillar, the B-pillar, and then the C kind of extends into the trunk, the little section across the dash there, and then the entire roof. And from that, we’re going to be able to put it on here on the Model 3 and start breaking down, you know, fitment cuz that’s what it really is going to be is fitting piece by piece after this to the Tesla. So, I’ve got an example here of things that are going to get trimmed next week or we’re going to come off here. We’re going to trim a lot of that. We’re going to trim all the way along to here. I got to figure out how to how to kind of deal with the reinforcement of that um heavier gauge. You know, I’m not going to call it frame, but it’s the kind of frame material of a unibody. It’s a trip, man. This is a big big project. So, I thank you guys for staying with me if I haven’t said it yet this week and you’re well, if you’re already here, let’s just face the facts. If you’re here at the end of somewhere between like 20 and 40 minutes, you’re one of my people and I appreciate you and you’re probably going to watch the videos. Those people who just dive out after a couple seconds, you’re like, “You did not give this a chance, did you?” But, uh, anyway, guys, I’m sure you’re liked, you’ve subscribed, make a comment this week. say, “Hey, doing great. Give me something.” Um, you know, it just helps build the channel, but it also helps emotionally to know I’m uh I’m not wasting my time making these videos. Like I said before, I’m going to build the car no matter what. Almost tripped over something. Um, it’s just the extra time that goes into putting it together for everybody to see. So, I appreciate you guys. Thank you. [Music] I don’t think we’re going to get it quite that low, but we’ll try. [Music] Hey, [Music] hey, hey. Heat. Heat. [Music] No, no, no. [Music] Heck yeah. [Music] Wake up. [Music] Do we know? [Music] Heat. Heat. N. [Music] Heat. Heat. [Music] All right. Even after all that chopping, we still hit a lot of stuff before we we don’t, you know. Um I think what’s going to happen, I’m going to take the bottom of this door off. Cut up in here. Cut up over there at the bottom of the hinge in the front and see how far that’ll let me drop it. And I’m going to sit back and think for a minute and then we’ll see where we’re at. Obviously, this is 8 in too high right there. Um, which isn’t really down to the bottom of the rocker. I’ve got that space, right? Like to look right. I just think I’m going to have to like bring the bottom of the door up and make the skin of the door go under or make a short door with a long rocker, something like that. Anyway, we’ll figure that out. Right now, it’s good day of chopping. Let’s uh take a minute here and breathe. All right, I’ve made decisions. I’m going to cut that bottom rail off. I know up here and down there at about 4 in up. I see where that sets. I can reattach this front rail and position it all. I’m not worried about that. I just got to get this down and I’m get that that’s where I want it. So that’s what I’m doing. [Music] I think I like this. It’s uh it’s actually the right height inside. So, even though this is floating, it doesn’t give us that big of a gap to fill on the top here. Um, I can do that with like either a piece of the original dash, wherever that is, or make a nice rolled piece, upholster it or something. Um, gives me room there for my uh wiper motor to run the wipers. Most importantly, when I’m sitting in the car, it feels right. Um, obviously there’s more to check right now, but I don’t hate where it’s sitting. So, if anything, the next round will be starting to tack things in place and then square them. So, so we’re going to start somewhere, you know, center post and move the front. Make sure all that’s square. Square the rear up. Um, and then start fitting doors and stuff like that. So, it’s ridiculous amount of work left here, people. Um, so unfortunately, this is kind of like a short video today to just get us to where we are. And, uh, next time we’ll be back with a lot lot lot more. Uh, I hope you guys are digging it all. Like, subscribe, all that. I appreciate it. Uh, leave a comment. You know, even saying that you think I’m nuts, I don’t appreciate those so much, but they do help. Uh, just knowing people are watching and all that. So anyway, that height is right. And then if we bag it or anything, that’ll be even better. But I can get in and out right there, which is the most important part is that this car is going to be drivable. When I’m sitting there, I’m looking out the window. Perfect. Um, so I’m pumped. I’m going to keep going. All right. I uh I put one fender on with a screw and a box and whatever. But to give you an idea here, but I think we’re heading down the right road. Look at that. Wheel lines up great. I think it’s going to work. I’m going to pull that fender off. I got some new wheels and tires, so I’m going to try those and see if I suck in the width of them a little bit. And if I do, that’s a win. [Music] We are wrong. [Music] Watch your eyes. [Music] Okay, those are on. They’re a different look for sure. [Music] 7/8 of an inch difference. So, the factory wheels 71 and 3/4. The black wheels 70 and 7/8. Just the tires are a little skinnier. Offset’s essentially the same. Everything else is the same. Just the tires are both skinnier. Um, I don’t know. I’ve gotten used to those other wheels now, but I do think that these are probably the way I’m going. They’re um they’re weight rated correctly. The tire is weight rated correctly. They’re a hair thinner than those. Their price is about the same. These aren’t expensive tires. None of these are. They’re hundred and something dollars a piece, you know. It’s not like the old days where a 20 in or something was $300. Crazy. Um, it’s just a matter of what looks right, you know, and that’s that could be debated. Those are cool in their own right, and those are cool in their own right. These definitely say I’m an electric conversion. Those sleeper electric conversion, so it’s just kind of uh I don’t know. I guess I guess I got to think about it a little bit. They bring it in a hair, which is nice because I could save myself from really wide man in the front. Maybe just a little bit unnoticeable. Um, but then I need caps. I need things to make them look cool. Anyway, none of that’s our worries. Just thought I’d throw that one more thing in here. Other than that, I think I’m done for the week. Um, the rest of the week I’m going to uh the Bailey metal shaping class in Vegas. Gonna go to SEMA for a day, walk around um and hopefully stop off in Buckeye, Arizona, which is not on the way, but it’s out of the way enough that I can go there and go back um and pick up some parts for a different car. So, anyway, that’s uh that’s going to eat up a couple days. So, this is where we’re going to get to right now. which I think is a good point. I mean, I’m going to make some panels, some things to hang doors and do all that. It’s It’s going to work. So, I’m actually pumped on it. Um, yeah, it’s going to turn out great. Thanks, guys. [Music] [Music] I mean, that almost tucks, but I don’t actually know where the fender is right now. Looks straight, but it’s probably not. Um, I don’t know. I don’t know. I don’t know. This is part of the creative process here, people. you know, to try some things and see what works and see what what says it’s right in the end. I’d hate to go back to those other wheels, but something about these just isn’t calling me right now. So, we’ll see how it goes. 7:30 p.m. on Thursday. Heading out to go to Vegas. Yep, I got my stuff together, man. Um, anyway, I’m spending the night there. going to SEMA tomorrow morning and then going to the metal working class. After that, Bailey’s metal working class and then after that going to my hotel, going to bed, going to the metal working class, going so we’ll see how that goes. Uh just checking in, heading out now. I’m not going to bore you with the drive to Vegas. It looks like driving to Vegas. All right. [Music] [Music] Hey, hey, hey. [Music] Hey, [Music] hey, hey. [Music] Heat. Heat. [Music] Hey, [Music] hey, hey. [Music] [Music] Hey. Hey. Hey. [Music] [Music] [Music] Okay. [Music] Hey, hey, hey. [Music] Man, it’s been a long weekend. Uh heading home is Monday and uh I got the pneumatic power hammer in the back there. You can sort of see it behind me. A huge addition to the shop. Uh although probably infrequently used, when it’s used, it will be amazing. So, I’m excited to have that. Uh it was a big uh big commitment. So, yeah. But, uh I’m happy to have it. And uh yeah, that was a cool event. So, going home, going to get back to work on the car. Uh hopefully this whole trip is super quick in your guys’ opinion. Um but I figured I’d throw it in there, you know, just little highlights of SEMA. Um like 2 seconds of the class because honestly, I was just busy. I was uh participating and I didn’t want to be, you know, taking videos and trying to do that whole thing. If you want to go to one of these classes, I suggest it. Um maybe maybe I’ll explain a little bit more, but it’s a really good thing. Look it up online. Bailey’s um metal shaping or metal fest. I know they’re doing another one next in Texas. So, see if you can get online and go uh do one of those classes. You also can do one through uh if you’re up in Canada, go to Carl uh Fiser in um wherever he is uh Mission area of BC or in Ohio the you go directly to Mike um and do a class with him and that those are worth it for sure. It definitely increases your skill level just for a couple days of learning and participating with that. So anyway guys, hope you enjoyed that. Uh I’m heading home and uh going to get back to work. Hey guys. So I’m home. You see the barn? What a long weekend. It was fun. It was a really good time. And the class was great. Mike Wagner, great teacher. Uh the other guys, uh Christian Sosa, Kevin Stone, the dude who did the bead roll in. I’m sorry I don’t remember your name right this second. And um the other guy who is Power Hammer and the Hot Rod Kid. I’m going to put the other two guys names up cuz I genuinely I just don’t remember right this second. Um what great instructors. I mean, every one of them had something to offer that I learned something from. every one of them, you know, took the time to make sure that we all kind of grasped the information if we wanted to. And then, uh, you know, I got to use every type of of power hammer that Bailey offers. And I’d already used the one that was at, um, this is my memory, guys. I mean, see, in like a couple years, I’ll be gone. I hope not. I hope not. Uh, Carl Fisher shop, though. He has some Mitler Brothers. um which is like one of the most affordable ways to get into a power hammer. The kit’s like 4,000 plus a couple thousand for dyes plus the metal to build it yourself and the time to build it yourself. And it’s a Yodar style hammer which is a beast. Okay. Amazing. Wonderful. You should own one. I should own one. We should all own one. Loud as could be as well. Um, and then I got to use the Bailey’s products, Bailey products. Um, they’re like midsized hammers that are 20 grand. They’re little guy, which is 12 or 15 with all the anvils. And then the one that’s like 30 with anvils and all that kind of another midsize. Uh, they didn’t bring their monster monsters, but they had, you know, good size hammers there. And then they had this one that I picked up. Tada. It’s the uh Bailey PH-28A. Retail 9,500 bucks or so. 92 on sale. Um shipping all that stuff too, but and tax. But we got a little deal on this, a little demo deal. So I took it because it made it affordable for me. It’s half the price of the similar sized hammer, but a standard um I don’t even know what the difference is, what you’d call that one, but mechanized as opposed to a pneumatic. So, the other one has a 220 electric motor. And this one’s got a little pneumatic hammer there. It’s kind of like a planishing hammer. Everybody can say it’s just a big planishing hammer, but even if it’s a big planishing hammer, it’s a big planishing hammer. And a planishing hammer is extremely capable. So, this thing’s a beast. I used it there. I actually before I even like knew what it cost and all that, I just kind of was trying hammers and I like the way this one operated. Um, it’s a little slower, a little smoother. So, you know, maybe maybe it’s because I’m not super familiar with them that it just felt more comfortable. It felt more like it was the one for me. It was calling my name saying, “Justin, let me come home with you.” Um, so we worked a deal and heck, it came home with me. So, I’m going to get it unloaded. I’m just setting it in the front of the garage. Garage is a freaking shop. Whatever. A mess right now. So, I’m going to have to sort that out. Um, the good news is that oh, the meteor is looking killer. Take another look at this thing. I know you guys saw it just like this the other day, but I mean, come on now. That is awesome. This thing is coming together. Nothing’s welded on yet or anything, but you can see it fits. You can see how poorly it would have fit here. I mean, the, you know, shell of the door is perfect alignment with that tire. But the way these are, they just come whoop way in. So, I’d have to spread this like way out to there and make big filler panels. And uh I mean we still might do it that way. We might do it that way. We might go back to the original. Somebody used the word sleek uh to describe this thing. I don’t know if I’d call it sleek. It’s It’s got a nickname. We all call these shoe box Fords, right? Cuz they look like a shoe box. They’re just blah, you know? They’re cool, but they don’t have much to them. They’re a box. So, I’m really leaning towards those caddy fenders if they can work out. And now with the big old Bailey hammer, we’ll be able to make the fill panels look really good. Look, I’ll show it to you from this side again. Look at that thing. I can’t wait to get doors on it and uh get that skeleton in place. But, uh yeah, just more work, more work, more work. I got a bunch of garbage piled up right there that’s just got to go boxes from stuff. Um, but mostly excited about the new hammer and uh obviously I’ll be putting out, you know, work with this in the videos for this car and I’ll probably do a big rundown video on this hammer in case you have any interest in them cuz to me I know nothing about it. That’s how I went into the weekend and now I’m in love with it. I think it’s great. So, I’ll put up a nice long video on it. You don’t have to watch that one if you’re not interested. But I think it’ll be a helpful one to anybody who’s kind of shopping hammers because I know I’ve been looking for hammers now for a couple months. And man, it’s hard to make a decision. And I really like the way this one is. So, I’ll put out more content on it uh independent of the car build. The car build’s kind of its own thing. So, anyway guys, I’m going to move this thing in and then I’m going to bed. I’m home. I’m tired, but tomorrow I’ll be out in the shop getting stuff done. You’ll see that cuz this is I don’t know. Maybe this is the end of last week. Maybe this is the beginning of next week. I think this is the end of last week. I think this is the end of last week. So, [Music] I should probably mention I think this weighing 900 950 lb 8.95 something like that. It is solid. Uh not that my big gym had no issues moving it, but it is a massive machine. It does not it’s not running away. But uh yeah, I can’t wait to get it. All that has to happen genuinely. You just put air to it. Boom. It’s running. So it’s it’s a great easy install machine. Uh it will have to get bolted to the floor if I figure out where I’m putting it or when I figure out where I’m putting it. For the moment, I’ll probably just spin it around and put it against the wall here. Um, but I do have to do drywall over there. Maybe I’ll put it over there by the tire machine. I don’t know.

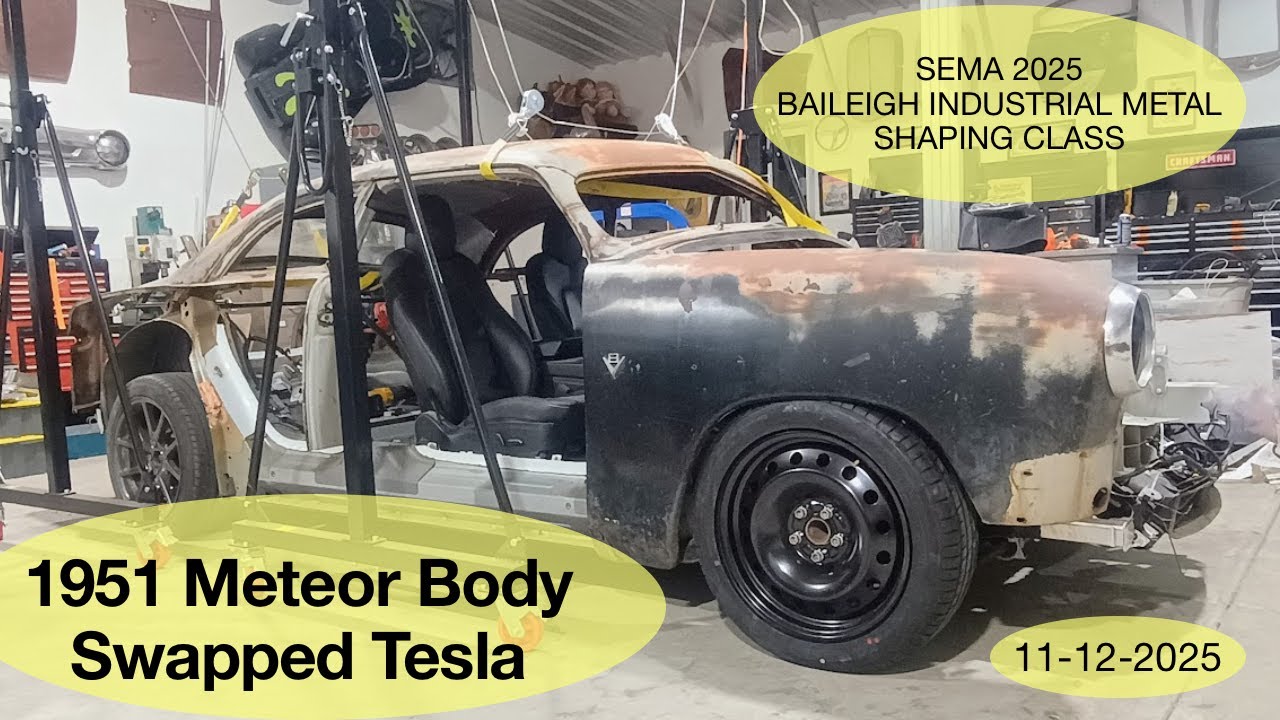

In today’s video, we finally set the upper section of the 1951 Meteor (Shoebox Ford) onto the 2020 Tesla Model 3 chassis/unibody!

This is a huge milestone in the Tesla-powered classic car build, and we’re getting one step closer to merging vintage style with modern EV performance.

Before the next phase of fabrication, we take a quick road trip to Las Vegas for the Baileigh Industrial metal shaping class, followed by an inspiring visit to SEMA 2025 to check out the newest tools, custom builds, and fabrication ideas.

If you’re into custom car builds, EV swaps, classic cars, metal shaping, or Tesla conversions, this is a build you’ll want to follow!

🔧 Don’t forget to like, comment, and subscribe to follow the full build series!

SPECIAL THANKS TO ……

@cornfieldcustoms

@BaileighIndustrialLtd

@hrkdesignvlogs

@CatskillMtnCustoms

@metalsculptorkevinstone431

@Twistedmetalsigncompany

@sosametalworks