Support CleanTechnica’s work through a Substack subscription or on Stripe.

Or support our Kickstarter campaign!

Though the political winds currently are blowing against clean, renewable electricity and sustainable transportation in the US, fortunately, in other countries, investment in such technologies continues. The UK-based startup Polaron recently raised $8 million. Racine2, an investment fund, led the raise, with co-investment from Speedinvest and Futurepresent.

While the focus on electric vehicles by members of the public lies mostly on the vehicles themselves, suppliers and manufacturers must develop enhanced materials to improve EV efficiency. As just one example, the electric MINI Countryman SUV had its range boosted by enhancing its technology without increasing the battery pack size. Similarly, materials science and discovery can be used to improve batteries.

Isaac Squires, Polaron co-founder and CEO, answered some questions for CleanTechnica.

How have early deployments improved energy density of battery electrodes by more than 10%?

Early deployments focused on manufacturing rather than chemistry. In battery systems, the materials themselves often get most of the attention, but how those materials are processed is just as important.

In batteries, you can keep the same materials and chemistry, but change how an electrode is processed and see performance move significantly.

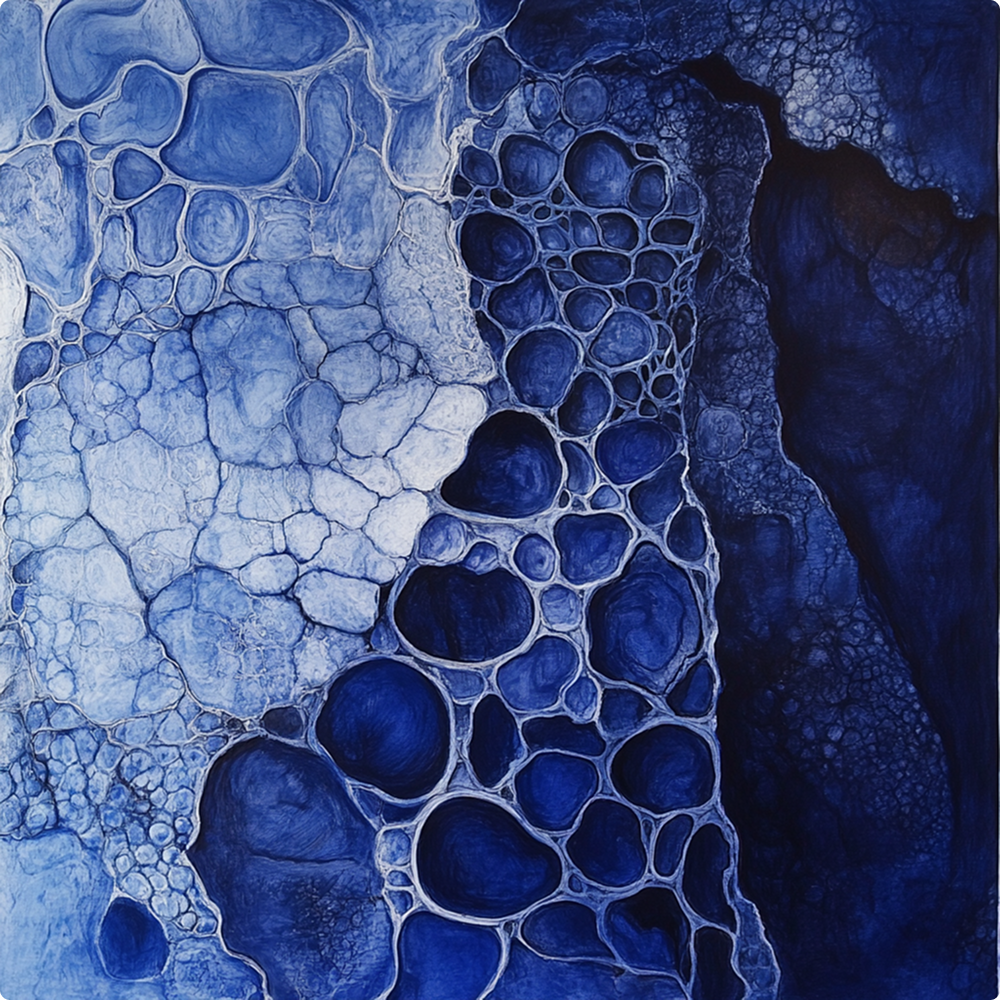

Polaron analyses microscopy images of battery electrodes to understand how steps such as mixing, drying, and compression shape the internal microstructure of the material. That microstructure determines how efficiently ions move through the electrode, how degradation develops, and ultimately how much energy can be stored.

By using this insight to redesign the manufacturing recipe, rather than the chemistry, early users have achieved energy density improvements of more than 10% in next-generation electrode designs.

Is there room for greater energy density improvement?

Yes. The gains seen so far reflect optimisation within existing materials and production lines, not a hard physical limit.

There is rarely a single ‘best’ electrode design. What matters is how you optimise the process for the materials and equipment you already have, with the end use case in mind.

In practice, many manufacturing parameters are still adjusted conservatively or one at a time, because physical testing is slow and expensive. By allowing engineers to explore a much larger design space digitally, Polaron opens up further headroom for performance gains that would be difficult to uncover through trial and error alone.

How is Polaron used to study the properties of materials? Does it study materials at the level of atoms?

Polaron does not operate at the atomic scale. We work at the microstructural length scale, which sits between atoms and full components.

At this scale, materials are made up of particles, grains, pores, and fibres that form during manufacturing. These structures are visible under a microscope and have a major influence on performance, especially in energy systems. Polaron uses microscopy images to study this internal structure, learning how it is created by processing and how it affects real-world behaviour. This complements atom-level AI tools rather than replacing them.

How do EV makers use Polaron?

Polaron is used by EV makers and battery manufacturers primarily within R&D and process engineering teams.

One use is characterisation: automating the interpretation of microscopy images so engineers can understand what they have made, across thousands of samples, with less subjectivity. Another is design: using AI models to predict how changes in structure and manufacturing parameters will affect performance, and to identify realistic ways to improve it.

Instead of relying on experts looking at images one by one, teams can analyse thousands of samples and explore thousands of process variations digitally. This helps accelerate work on fast charging, energy density, and battery lifetime, all of which are critical to EV adoption.

What will the new funding be used for?

The funding will be used mainly to scale the team and expand industrial deployment. We’re a team of nine today and expect to more than double by the end of the year.

The focus is on hiring across AI research, software engineering, and materials science, while continuing to advance the core technology. It also supports deeper integration with large industrial customers.

Can Polaron be used for other EV components to improve them?

Yes. The approach is not limited to battery electrodes. The process–structure–performance relationship is universal across solid materials.

Beyond electrodes, the same methods can be applied to structural metals and alloys, composite materials, coatings, and other electrochemical components used in electric vehicles. Any component where performance depends on internal structure, and where that structure is shaped by manufacturing, can benefit from this kind of materials intelligence.

Support CleanTechnica via Kickstarter

Sign up for CleanTechnica’s Weekly Substack for Zach and Scott’s in-depth analyses and high level summaries, sign up for our daily newsletter, and follow us on Google News!

Advertisement

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Sign up for our daily newsletter for 15 new cleantech stories a day. Or sign up for our weekly one on top stories of the week if daily is too frequent.

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy