Those of you who follow me know that I have a thing about batteries and electrical power storage. I live on a boat and with my solar array and wind generator it’s a constant concern to avoid using a generator and ensure that my freezer has enough juice. I’ve been writing here about power storage systems and technologies for several years and still the stories keep coming!

This recent news has generated intense interest — and intense scepticism — with the technology said to be available ‘now’ on Verge’s electric motorbikes. It’s a potential paradigm shift.

Motorbikes are not my thing, and the sight of that hubless rear wheel scares me to death. But the batteries are worth looking at.

News

In a significant development at the 2026 Consumer Electronics Show, Donut Lab announced the commercial availability of its all-solid-state battery technology.

This innovation is the result of Donut’s strategic partnership and investment in Nordic Nano, a Finnish specialist in nanotechnology. The companies confirmed that the technology is no longer confined to laboratory testing but is currently being integrated into production vehicles.

The first application of these cells is found in the 2026 Verge TS Pro and Ultra motorcycles, which are scheduled for delivery in the first quarter of the year.

This announcement marks a shift in the electric vehicle industry, as it represents the first instance of solid-state power units reaching the market at a commercial scale, bypassing the protracted timelines often associated with this technology.

If true.

The underlying technology

The technology developed by Nordic Nano replaces the flammable liquid electrolyte found in conventional lithium-ion batteries with a solid-state architecture.

The cells utilise advanced nanocarbon materials, including carbon nanotubes and graphene, to create a stable and highly conductive internal environment. These materials enable a claimed energy density of approximately 400 Wh/kg, which is a considerable increase over current industry standards (~74% more).

A defining characteristic of this technology is its apparent thermal stability. The solid electrolyte prevents the formation of metallic dendrites, which are the primary cause of thermal runaway and fires in lithium ion batteries.

The use of plentiful and geopolitically secure materials ensures that the production process does not rely on rare earth elements or cobalt. The resulting units are capable of achieving a full charge in approximately five to ten minutes and can sustain up to 100,000 charge cycles with negligible degradation.

The claims

Nordic Nano claims that its solid-state architecture significantly enhances energy conductivity by utilising a nanocarbon framework. This structure creates high-surface-area pathways that facilitate rapid ion movement, resulting in superior efficiency during high-power discharge and ultra-fast charging.

Thermal stability is an inherent feature of the solid electrolyte, which is non-flammable and eliminates the risk of thermal runaway.

Beyond that they claim that the technology exhibits extreme resistance to degradation; the company asserts that the cells maintain 99% capacity at -30°C.

Validation

It is all hype?

Formal validation of these claims remains limited to internal testing by Nordic Nano and Donut Lab.

While the firms assert that the technology has been “fully validated” through vehicle operation, no independent third-party reports or peer-reviewed academic papers have been released to the public. Consequently, the performance metrics await proof through real-world consumer use in the first quarter of 2026.

Patent status

The status of patents for the solid-state technology developed by Nordic Nano and promoted by Donut Lab is a subject of significant industry debate. Specific patent filings directly attributed to these entities regarding all-solid-state chemistry are not currently visible in public databases.

The intellectual property appears to be rooted in the use of nanocarbon materials.

Nordic Nano focuses on the application of carbon nanotubes and graphene to create a conductive framework within battery cells. These “smart materials” are designed to enhance conductivity and structural integrity. However, industry analysts have noted a lack of peer-reviewed scientific papers or direct patent links to the specific solid-state battery architecture claimed during the 2026 Consumer Electronics Show.

This absence of public documentation has led to doubts regarding the novelty of the technology.

The company maintains that the technology is fully validated and operational in Verge motorcycles, implying that the intellectual property may be protected as trade secrets or exists within pending applications that have not yet reached the eighteen-month publication threshold.

The products

The new battery technology is currently being integrated into the Verge TS Pro and the Verge TS Ultra motorcycles. These models were shown at the 2026 Consumer Electronics Show as the first production vehicles to utilise the all-solid-state chemistry developed by Nordic Nano and Donut Lab.

Verge TS Ultra. Screengrab from Verge Motocycles website.

Verge TS Ultra. Screengrab from Verge Motocycles website.

According to technical specifications released during the event, the flagship Verge TS Pro is equipped with a 33.3 kWh battery pack.

This unit enables a range of up to 600 kilometres (approximately 370 miles) on a single charge.

The motorcycles are designed to support 200 kW fast charging via the North American Charging Standard (NACS), allowing the battery to reach full capacity in approximately ten minutes.

These models are scheduled for initial customer deliveries within the first quarter of 2026, so it shouldn’t be long before we know the truth.

Comparison

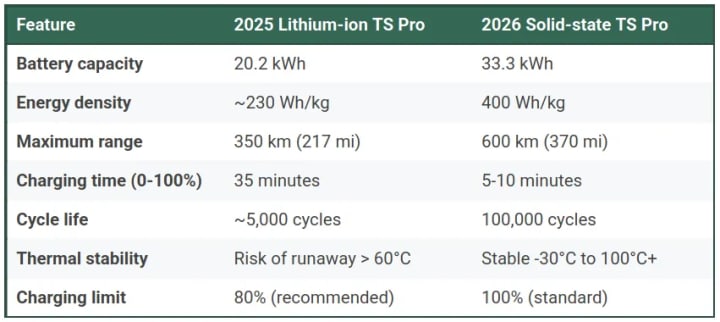

Here is a comparison between the current version of the Verge TS Pro (lithium ion) and the upcoming solid state version.

Author table. Data based on claims, not verified yet

Author table. Data based on claims, not verified yet

The most significant advancement is the energy density, which has increased from approximately 230 Wh/kg to 400 Wh/kg.

This 74% improvement allows the 2026 model to house a higher capacity within the same physical dimensions, nearly doubling the effective range.

The removal of the 80% charging cap — a requirement for preserving the health of liquid electrolytes — enables users to utilise the full capacity of the battery without increasing the rate of degradation.

Implications

The introduction of solid-state technology has profound implications for the design and utility of electric vehicles.

The high energy density allows for the creation of lighter battery packs, which improves vehicle efficiency and handling.

In the case of the Verge motorcycles, this has enabled a range of up to 600 kilometres on a single charge. Because the batteries do not require complex liquid cooling systems to maintain safety, manufacturers can reduce the overall weight and complexity of the vehicle chassis.

The rapid charging capability also addresses the primary barrier to widespread electric vehicle adoption: charging time. I know a bit about this because in an earlier life I used to run a fleet of electric milk floats, each with 2 tons of lead acid battery.

By reducing the time spent at a terminal to a duration comparable to refuelling an internal combustion engine, the technology makes long-distance travel much more practical.

Additionally, the extreme temperature resilience of the cells, which retain 99% capacity at -30°C, ensures reliable performance in northern climates where traditional batteries often struggle.

Charging challenges

EV owners know about this issue, but it’s compounded with this new technology.

Although the recharge time may be very rapid, the infrastructure to provide that rapid charge is sparse. Recharging the Verge TS Pro at its maximum 200 kW rate requires a direct current of approximately 500 amperes, assuming a 400-volt architecture.

To achieve the advertised ten-minute charge, the motorcycle requires a charger capable of delivering a constant high current. On a standard home 7 kW AC charger, the Verge would take over five hours for a full charge, nullifying the primary advantage of the Nordic Nano technology.

The optimum demand exceeds the capacity of standard residential electrical grids, which typically support only 7 to 22 kW. Consequently, users must rely on specialised public DC fast-charging infrastructure, as household circuits cannot deliver the high-intensity current necessary for ten-minute charging.

However, the increased range and access to that last 20% of charge in the battery arguable puts less pressure on recharging issues.

Challenges

Despite the successful launch, several obstacles remain for the widespread implementation of this claimed technology.

Scalability

Scaling production from specialised motorcycles to high-volume passenger cars requires the establishment of large-scale manufacturing facilities, often referred to as gigafactories. The current production volume for 2026 is limited to a few hundred units, which serves as a real-world pilot for the technology.

Business disruptor

Transitioning to a new material supply chain and assembly process requires significant capital expenditure. EV companies currently already have a long-term capital commitment with invested plants, which they will want to recover.

So, the opportunity arises for a market disruptor. Remember PCs and IBM’s bad decision to protect their big iron? Then there was Hoover which ignored Dyson’s vacuum cleaner technology patents and he successfully sued them into the ground.

There is also the challenge of industry-wide integration. Donut Lab has partnered with firms such as Watt Electric Vehicles to develop modular platforms.

Furthermore, the long-term durability of these nanocarbon structures in varied road conditions will only be fully proven once the first fleet of vehicles completes several years of service.

Conclusions

The collaboration between Donut Lab and Nordic Nano has resulted in a real advance in energy storage, but yet to be proven.

By delivering a production-ready solid-state battery that exceeds the performance of lithium-ion alternatives in safety, density, and longevity, the companies have set a new benchmark for the sector.

While the initial rollout is limited in scale, the successful integration into consumer vehicles suggests that the era of solid-state mobility has commenced. This should grow the market, provided always that the issues of charging infrastructure can be overcome.

The success of this technology will probably depend on the ability of the partners to scale their manufacturing processes and the subsequent response from established automotive manufacturers. We could see big disruption in the EV market. I will not cry if Musk’s Tesla gets a hiding.

The really good news is that the materials used are plentiful and not geographically strategic. That mean inexpensive.

***

This is an edited version of the story first published on medium.com

(c) James Marinero 2025/2026. All rights reserved.