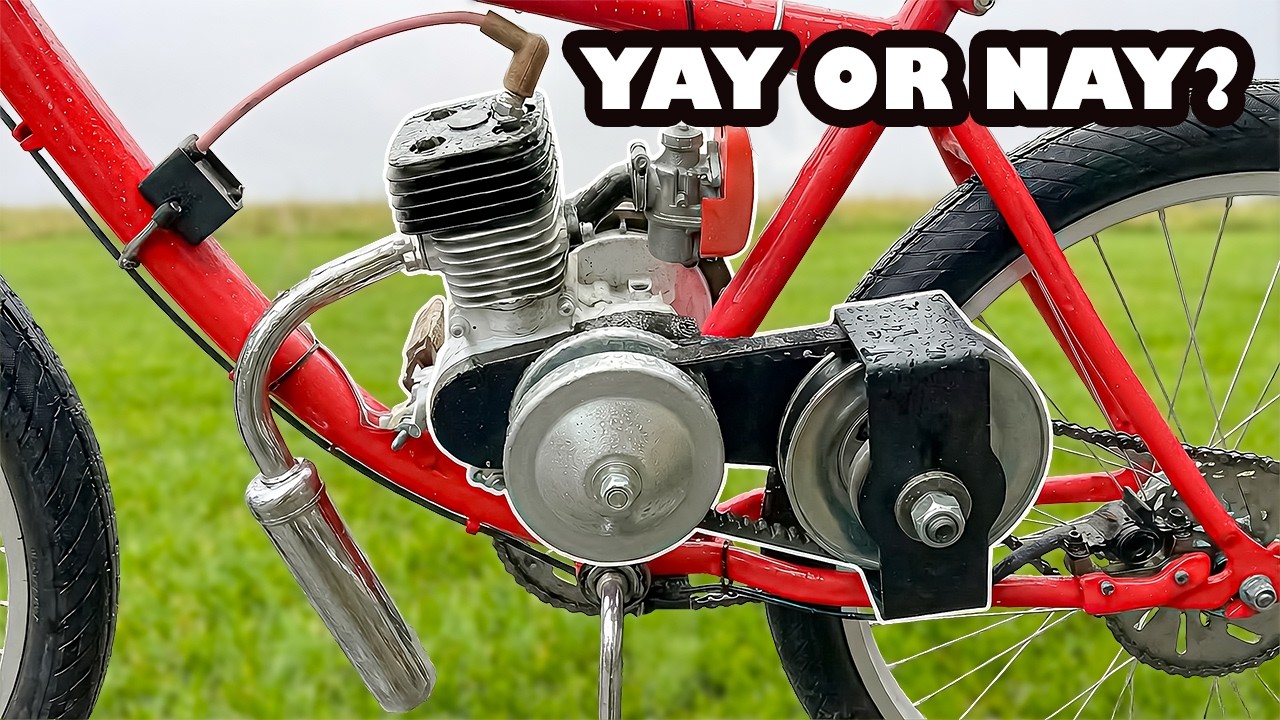

I put a CVT on a motorized bike kit. was it worth it?

All right, guys. So, in a previous video, we put a torque converter on one of those classic motorized bike uh engine kits. There we go. We’re going to finally get this thing on a bike, put some wheels on [music] this frame, and get it on the road. So, the rims are going to be some heavyduty uh motorized bike rims off of Amazon. All right. Then, I bought some big old thick wheels. Those suckers should be nice and sturdy while driving around. Unfortunately, the hub diameter is too large for this sprocket mount, so [music] I had to shave it down a bit. But at the end of the day, we finally got that thing to fit just nice and snug. So, I do see some motorized bikes where they just take the disc brake and mount the whole shebang like this onto [music] the disc brake hub. But with this size sprocket that I have, I’m not going to be able to get a caliper in here without scraping some stuff. So, um I just need to cut a circle into this. In the previous video, I set up this CVT system, but um it was more for the sake of the video and getting it to work rather than getting it to work with the bike. So, I have to redo all this because that bearing will just hit against the wheel and the sprocket won’t line up. have to figure out a way to make a bracket that comes over and then has a another bearing for this side. I also thought I was having issues with the belt being too loose, but actually the measurements are right on with the stock torque converter plate. So, using that same finale board stuff, I cut out a new mount. Yeah, look at all that cancer dust. These two did good, but I don’t know what the hell happened there. I decided I need one more bend on those outer pieces and that’ll help tie everything together. So, since these new tires are thicker than your mother after a Thanksgiving ham, I got to cut out these little brackets because they get in the way. And that looks pretty good. I was still having an issue where the sprocket shaft was getting way too close to the wheel. So, I decided to cut that part off. And I think that extra space should work just right. >> [music] >> Once I aligned the chain and fit it up, I took everything apart and then painted [music] the bracket. I still haven’t solved the issue of having no rear brakes, so we got to make ourselves a bracket for the disc brake. If you’re a welder, you might want to just look away. I don’t really have any way to weld aluminum and I’ve never done it before, but I do have an acetylene torch, so I tried my best. Look at these perfect dimes. Beautiful. So, I think that’s kind of a product of trying to weld two different chemistries of aluminum together. I think that bracket is on there nice and good. I was using this filler rod and it has a uh flux in there, I think. So, anyway, if you grind it, clean it up. It looks pretty nice. I noticed that the chain was kind of rubbing up against the disc brake cable, so I just cut up some gas tube and that’ll protect it. Oh, yeah. We still have the issue of the motor being in the way of the pedals, so we got to extend those. Well, guys, being a oneman show [music] here at Oliver Motorized, filming myself can be really difficult. So, when Hover Air offered to send me [music] their self-flying drone, I had to say yes because this thing is a game changer. [music] So, some things I really like about this thing is it is just super small and compact, so I can just fit it in my pocket, [music] no problem, and take it wherever I need to film. It comes with tons of different uh pre-programmed flight paths. [music] It’s super easy to sift through all the different modes that it has. It [music] can orbit. There’s a ski mode. There’s a spiral mode. And then, of course, my favorite is the bike mode where it follows me um while I’m riding the bike, which makes showing off my projects that [music] much better. One thing is the battery does go quick, but thankfully the package comes with a whole other battery, so you can just [music] quickly swap them out. So, just in time for Christmas, be sure to check out the link below and get yourself or a loved one a Hover Air X1 Pro Max. [music] I’ll be completely honest, I did a lot of that just by eye, but it turned out pretty good. [music] [music] [music] >> [music] [music] >> So, one thing is I was thinking about trying to modify this engine to get more RPM and then we could use higher force springs, but I think this is more meaningful if we keep the engine completely stock, stock carburetor. This is just a kit you get off Amazon. So, that’s kind of the idea behind this video. So, if you watch the previous video, we did a bunch of experimenting with different springs. We came up with using some stock springs from Ace Hardware and those are what are in there now. So, we’re going to start it up and see how these guys work. Well, right away I noticed that these springs won’t cut it. I was full throttle and nothing was really engaging. All right, went a whopping 12 miles an hour. All right, [laughter] let’s take one of those springs out and just see what happens in [snorts] that case. Let’s flop this guy out of there. It did get me going without pedaling, though, so I guess that’s a good sign. This is with one spring. Oh, that’s much better. Ah, that was a solid 18 mph. So, before the test ride, I went and bought few more spring options. This is like a very low force spring. This is probably the lowest I could find on there by itself and see how that goes. If we get 30, I’ll be happy with 30 mph. We hit 18 with that one. So, yeah, let’s try it. I guess I got to take this whole thing off for this guy. Dang it. With that new spring installed, [music] it was a world of difference. The initial torque was way better. And then also the top speed was very surprising, too. And as you can see from a standstill, [music] this thing has enough torque to get me going no problem. One thing I noticed was that the torque converter still wasn’t getting fully engaged. Looking at the driven pulley, it wasn’t sucking in all the way. So, there’s still room for improvement with this design. That’s just going to have to be more RPM from updating the motor. To be honest, I was disappointed at first, but we put that last spring on there and we’re hitting 30 and it has a lot of pickup. Like, uh, no pedaling required to get going. It goes up hills perfectly fine. That’s pretty awesome. I’m kind of surprised. All right, so the final question. Is it worth it putting a torque converter on one of these bikes? The truth is, I have no idea. I’ve never actually ridden one of these normally, so I can’t really tell you if this is better or worse. And I don’t know how those go um at a standstill. I’m kind of pleasantly surprised with just one little dinky spring in there. Anyway, let me know in the comments what you guys think. Is this something you would try? All right, it’s really starting to rain, so I got to go.

HoverAir WEBSITE: https://dada.link/GZhksk

Hashtags: #HOVERAir #X1promax #besttrackingdrone #followmedrone #selfiedrone

@HOVERAir_official

In this video, I show you the step-by-step process of installing a Go Kart CVT on a gas-powered 80cc motorized bike. These 2-stroke engine kits from Amazon are great, but the standard drive system leaves a lot to be desired.

Why use a CVT? Unlike a fixed gear, a Continuously Variable Transmission (CVT) allows the engine to stay in its powerband, providing massive torque for climbing and smoother acceleration.