BYD Unveils First Production Flat-Four Engine for Plug-In Hybrids

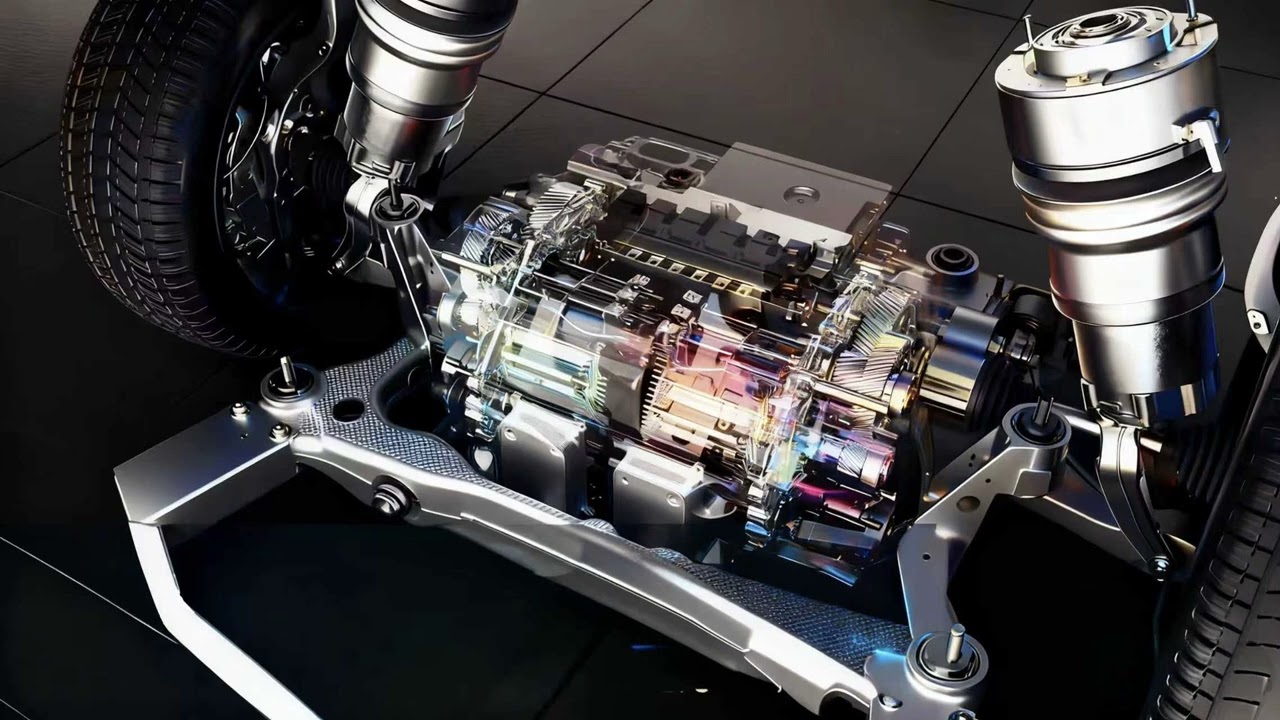

BYD unveils first production flat 4 engine for plug-in hybrids. BYYD has publicly deconstructed its newly developed 2 L turbocharged horizontally opposed boxer engine, marking the first time this engine type has appeared in a production plug-in hybrid vehicle. The detailed tearown presented with commentary from Professor Su Min of Shanghai Xiaoong University showcases a significant engineering achievement tailored for BYD’s E4 platform. Why this matters? Hybrid engine evolution. The introduction of a flat 4 engine into a hybrid system is notable. Traditional internal combustion engines are being reimagined as electricity generators in hybrid architectures where silent operation and compact design are crucial. Flat engines, historically favored for performance cars, are now being re-engineered to optimize space and reduce noise in plug-in hybrids. core design and amp benefits. Unlike conventional inline engines, the flat layout offers a lower profile and inherent vibration cancellation, which drastically improves noise, vibration, and harshness, NVH. This engine is first featured in the BYD Yong Wang U7 integrated into a compact front module alongside a generator, two drive motors, and the DI SUSC suspension system. The 2T boxer’s primary role is to generate electricity for the electric drive line, though it can also contribute torque directly to the rear wheels under specific conditions. The powertrain delivers 272 horsepower, 203 kW, and 380 Nm of torque. Technical optimizations for hybrid use to ensure maximum compactness and silence. BYD has implemented a dry sump lubrication system, a custom oil circulation design, and a cooling system optimized for the flat layout. Additional NVH reducing measures include a sandwich structure for end caps and dual timing chains. The company claims the engine generates only 1 dB more noise than the electric motors under idle and light load, rendering it nearly undetectable during normal driving. The engine’s physical dimensions are optimized for tight packaging, measuring just 420 in height. This design allows BYD to maintain a low center of gravity while maximizing space in the front compartment. Advanced driving capabilities. The E4 platform leverages the boxer engine to enable advanced driving modes such as crab walking and in place tight turns thanks to individually controlled wheel motors. BYD also highlights that the engine’s output can be dynamically adjusted based on the battery state of charge SO enabling more intelligent energy management. Pricing and amp availability. The Yong Wang U7 plug-in hybrid model launched earlier in 2025 with a starting price of 628,000 yuan, approximately $85,800 USD. while a four- seat variant is priced at $78,000 yuon, around $96,700 USD. In conclusion, BYD’s new boxer engine represents a strategic shift in hybrid technology by adapting a historically performance focused design for energy generation and compact packaging. The company demonstrates an innovative approach to plug-in hybrid engineering. This move underscores the growing trend toward optimized combustion engines in electrified vehicles, prioritizing efficiency, silence, and advanced driving capabilities.

Read more here: https://nanoprotec.in.ua/uk-uabyd-predstavila-pershij-serijnij-opozitnij-dvigun-dlja-gibridiv.html BYD Unveils First Production Flat-Four Engine for Plug-In Hybrids pBYD has publicly deconstructed its newly developed 2.0-liter turbocharged horizontally opposed (boxer) engine, marking the first time this engine type has appeared in a production plug-in hybrid vehicle. The detailed teardown, presented with commentary from Professor Xu Min of Shanghai Jiao Tong University, showcases …